Investing in robots: the Russian Federation has launched the production of smart technology components

- Статьи

- Science and technology

- Investing in robots: the Russian Federation has launched the production of smart technology components

For the first time, Russia is launching the production of fully domestic micromotor gearboxes - components necessary for the operation of exoprostheses, robots, satellites and embedded intelligence technologies when AI is placed in a physical object, such as a drone. A pilot batch of parts has already been released. Until recently, such micro-drives were not produced in our country, and enterprises were forced to purchase them abroad, which created risks for critical projects due to sanctions and supply disruptions, experts said. How import-substituted components will help the development of various industries is described in the Izvestia article.

The first Russian production of micromotor gearboxes

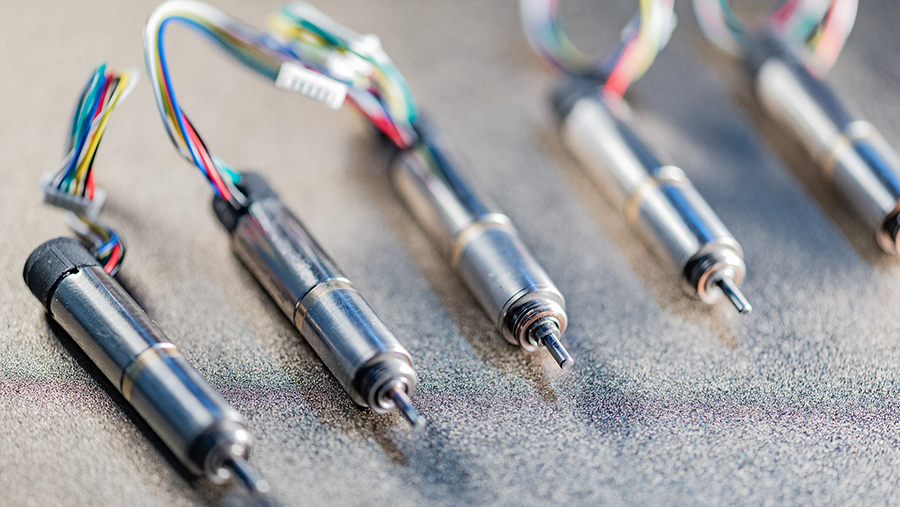

NUST MISIS engineers, together with specialists from the Karfidov Lab design Bureau, have developed fully domestic micromotor gearboxes (miniature motors equipped with small gearboxes) that can be used in medical prostheses, robotics and industrial automation. Devices of this class have not been produced in Russia before. A pilot batch has already been released, and mass production will be launched at a site in the Tula region.

As the scientists explained to Izvestia, miniature electromechanical systems — micromotor gearboxes — ensure natural and smooth movements of artificial joints, as well as stability and precision of their control. The development included the analysis of foreign analogues, three-dimensional scanning, creation of digital models, computer calculations of the behavior of parts under load and testing of prototypes.

As a result, engineers have created two product sizes — the DPR-8 (with a diameter of 8 mm) and the DPR-10 (10 mm), which are characterized by compactness, high efficiency and precise control.

— The technical solutions that we have applied allow us to use unified components for different models of gearboxes. All standard sizes are equipped with a single compact sensor that converts motion into a digital signal. This simplifies assembly and makes the parts interchangeable. We hope that our development will be useful to domestic manufacturers from various fields: medicine, agriculture, robotics, instrument and mechanical engineering, electronics and other industries," Alexey Karfidov, head of the University's Department of Technological Equipment Engineering, co-founder and General Designer of the Design Bureau, told Izvestia.

Import substitution of components in electronics

Against the background of growing interest in embedded intelligence, that is, in AI embedded in physical systems, such as robots, one should not forget that the embodiment of intelligence should be end-to-end, that is, it should not end at the top level of planning and decision-making, but should be implemented down to mechanics, said Professor, head of the laboratory of biomechatronics and energy-efficient robotics (BE2R) Sergey Kolyubin, ITMO University.

"The human body is a complex and intelligent mechanism, so it is strange to expect the creation of functional robots without progress in hardware, including such important building blocks as drives," the expert noted.

Own production of such parts is important enough to ensure the technological independence of the country, Ruslan Permyakov, deputy director of the NTI Competence Center "Technologies of Trusted Interaction", told Izvestia. Until recently, micro-drives of such standard sizes were not produced in Russia, and enterprises were forced to purchase them abroad, which created risks for critical projects due to sanctions and supply disruptions.

— In addition to the obvious independence from other people's political will, such industries form their own engineering competencies in the fields of micromechanics, electrical engineering, materials science and precision engineering, based on practical skills. This is also critically important for creating complete product design and testing cycles, including mechatronic components for robotics, medicine, aviation and instrumentation," the expert emphasized.

According to an industry expert, micromotor gearboxes are used in systems where compactness, high precision and smooth movements are required. Potential applications include medicine and prosthetics — artificial joints, exoskeletons, robotic rehabilitation complexes, microsurgical instruments. They are also used in robotics and mechatronics, such as manipulators, service and industrial robots, microdrons, guidance and stabilization systems, Ruslan Permyakov said.

Other applications include industrial automation, aerospace technology (antenna orientation and deployment drives on small satellites, stabilizers in unmanned vehicles), agriculture and household automation (micro-drives in agrotechnical robots, smart home systems, 3D printers and precision metering devices), scientific instrumentation, the expert noted.

The project was implemented under an agreement with the Agency for Technological Development and is aimed at full import substitution of key components.

Переведено сервисом «Яндекс Переводчик»