Body of technology: Chemical robots will replace humans in laboratory experiments

- Статьи

- Science and technology

- Body of technology: Chemical robots will replace humans in laboratory experiments

Scientists from St. Petersburg have assembled and tested a robotic platform for automating chemical experiments. The robot independently, without human intervention, performs simple operations to trigger reactions of organic compounds. The development is more accessible and versatile than industrial systems, since it is assembled from parts printed on a 3D printer and has an open source code. The robot chemist has already helped to detect the acceleration of reactions in the environment of polymers — the discovery expands the possibilities for creating targeted drug delivery systems. Read more about the innovation in the Izvestia article.

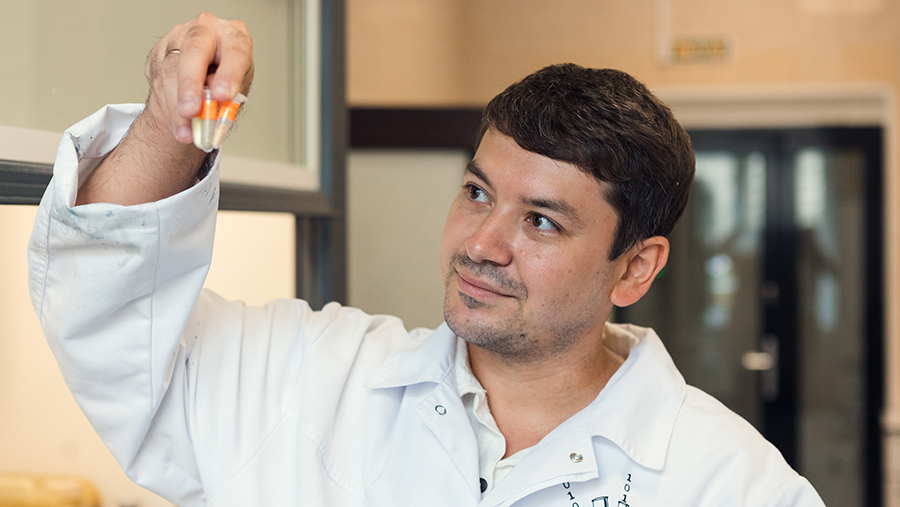

A robotic arm for working in a chemical laboratory

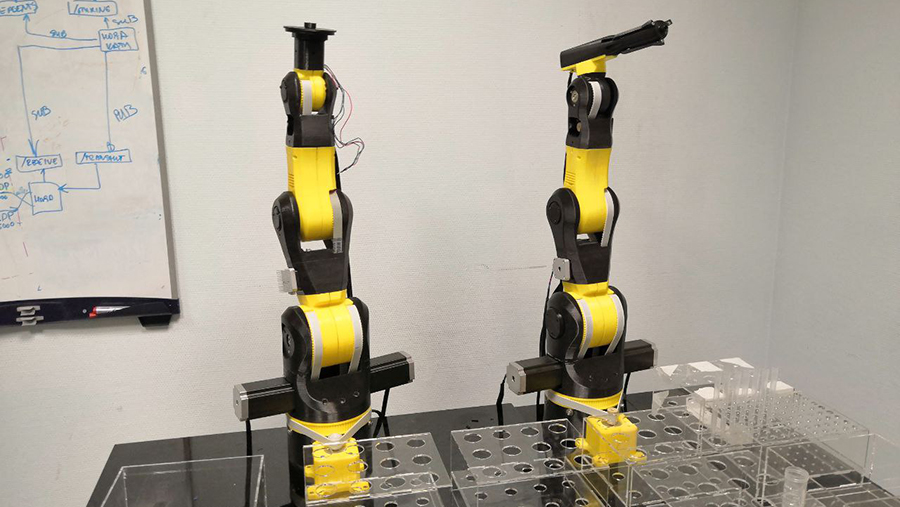

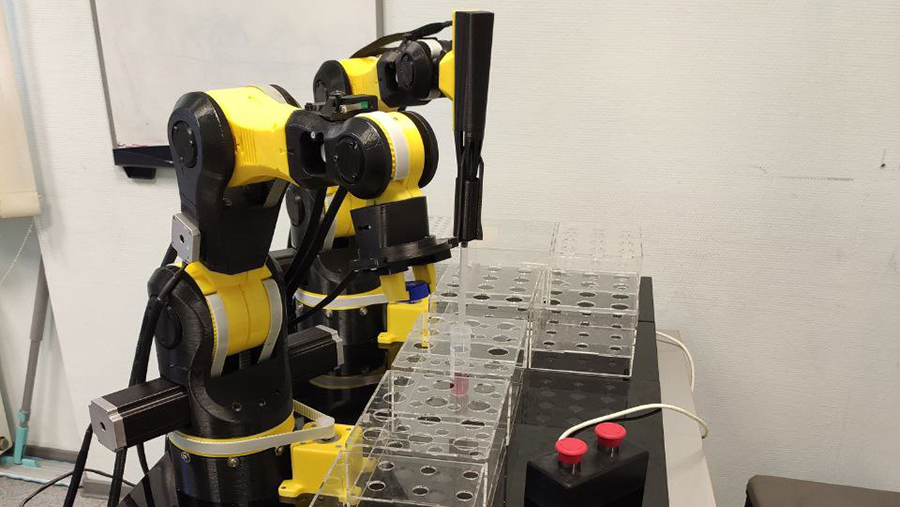

Chemists and roboticists at ITMO University's Infochemistry Center have developed an inexpensive robotic arm for automation and reaction research. As the scientists explained to Izvestia, it can be assembled from parts printed on a 3D printer. And the device runs on an open source platform.

The robot performs basic laboratory operations: unscrews the tube caps, prepares reaction mixtures, selecting the required volumes of reagent solutions and pouring them into tubes or cuvettes, transfers the tubes between different units, and installs the cuvettes in the spectrophotometer compartment. To do this, the machine uses a capture manipulator (robo-arm), a dispenser, a USB camera and a controller that processes information from the camera. The robot's "brain" is a data management and analysis program written by ITMO engineers in Python.

As explained to Izvestia at the university, when studying chemical reactions, scientists have to repeatedly perform a number of routine operations: select reagent solutions, mix them and control the reaction using physico-chemical methods. This can lead to the accumulation of fatigue and the appearance of accidental errors. And robotic manipulators, unlike humans, do not get tired and do not make mistakes, as they act strictly according to a given algorithm. This allows optimization for several parameters at once as part of experiment planning. In addition, robots can be used in dangerous conditions for humans, for example, when the reagents or reaction products are toxic.

— We propose to massively use our solution for educational and research laboratories: to assemble such a robot, you will only need parts printed on a 3D printer, and you can write the program code yourself or use code from open sources. With the help of such platforms, it is possible to successfully automate the tasks of extracting useful or, conversely, toxic components, as well as the search for new ways to accelerate organic reactions. In particular, with such technological assistants, it would be interesting for us to explore more complex, multi—stage reactions," Anton Muravyov, one of the main authors of the study, associate professor at the ITMO Scientific and Educational Center for Infochemistry, told Izvestia.

How can a chemical robot be used?

Using a manipulator, the scientists automated the organic reaction — condensation of barbituric acid with various aldehydes. It can potentially be used in biological systems to modify biomolecules. For this, it is important that the reaction can proceed quickly in environments similar to those found in the human body. According to the results of 45 experiments, the chemists managed to accelerate the reaction — in some cases, it increased more than three times. According to the authors, the discovery holds promise for medicine, for example, for imaging cells in cancer diagnosis or creating targeted drug delivery systems to specific organs, as well as for developing piezoelectric response materials used in microelectronics, vibration and pressure sensors, and ultrasound equipment.

Robots will find application in scientific research at institutes and universities and in product quality control departments at chemical enterprises, said Evgeny Alexandrov, Director of the NTI Center for Digital Materials Science: New Materials and Substances at Bauman Moscow State Technical University.

They can help automate processes in the chemical industry, petrochemistry, building materials development, pharmaceuticals, chemical and biological analysis in medicine.

— In research, for example, the synthesis of metal-organic coordination polymers, it is necessary to go through a huge number of options for the conditions of reactions. This routine work takes a lot of time from highly qualified employees. The robotic system will free them from routine, increase reproducibility of results, facilitate data collection, and focus on predicting the possibility of obtaining new compounds," the scientist said.

Robots in chemical production are a very promising area, because human participation in this industry can often be severely limited by a number of safety requirements, said Alexey Karfidov, Head of the Department of Technological Equipment Engineering at MISIS University.

— The robot can work in more difficult conditions and interact with substances that are harmful to humans. But it is still important to pay attention to the materials and coatings from which it is made, so that they are not spoiled by caustic chemicals with which experiments should be carried out. And in general, it is necessary to ensure high accuracy, especially in the case of working with small volumes of substances, so that there is the most efficient consumption of reagents for conducting experiments," the expert noted.

The results of the study are published in the journal Materials Horizons.

Переведено сервисом «Яндекс Переводчик»