The devil is in the details: the domestic car industry remains not entirely Russian

The actual level of localization of domestic cars turned out to be almost two times lower than planned. Because of this, there is a high risk of not achieving the goals set out in the Strategy for the development of the Russian automotive industry, experts say. The main problem is related to the shortage of components and components manufactured in our country, experts say. Izvestia found out how it is planned to solve it.

Goals not achieved

According to the results of last year, the weighted average level of actual localization of passenger cars produced in Russia was 32.8%. This was stated by Alexander Gorchakov, Director of the Center for Industry Analysis and Forecasting at FSUE NAMI, during the IMAF conference in Moscow. At the same time, according to the Automotive Industry Development Strategy adopted in 2022, it was expected to reach 55% by the end of 2024. Thus, the actual level of use of domestic components, assemblies, assemblies and technologies in the production of Russian cars turned out to be almost two times lower than stated.

Despite the fact that, according to the Strategy, the localization rate was supposed to increase to 60% from 2025, in reality it even went down. As follows from the presentation of FSUE NAMI (available to Izvestia), in January 2025 it amounted to 31.3%, and in February it increased to 32.6%. Meanwhile, the Strategy provides for another increase in the localization level of domestic passenger car models from 2026 to 65%. Taking into account the actual state of affairs with this indicator, FSUE NAMI assesses the risk of not achieving the stated goals as "high".

— The figures that we provide are confirmed by the documents of the Chamber of Commerce and Industry. We have reliable, honest, and truthful information. These indicators are calculated by the information and analytical database of FSUE NAMI," emphasized Alexander Gorchakov.

The solution program

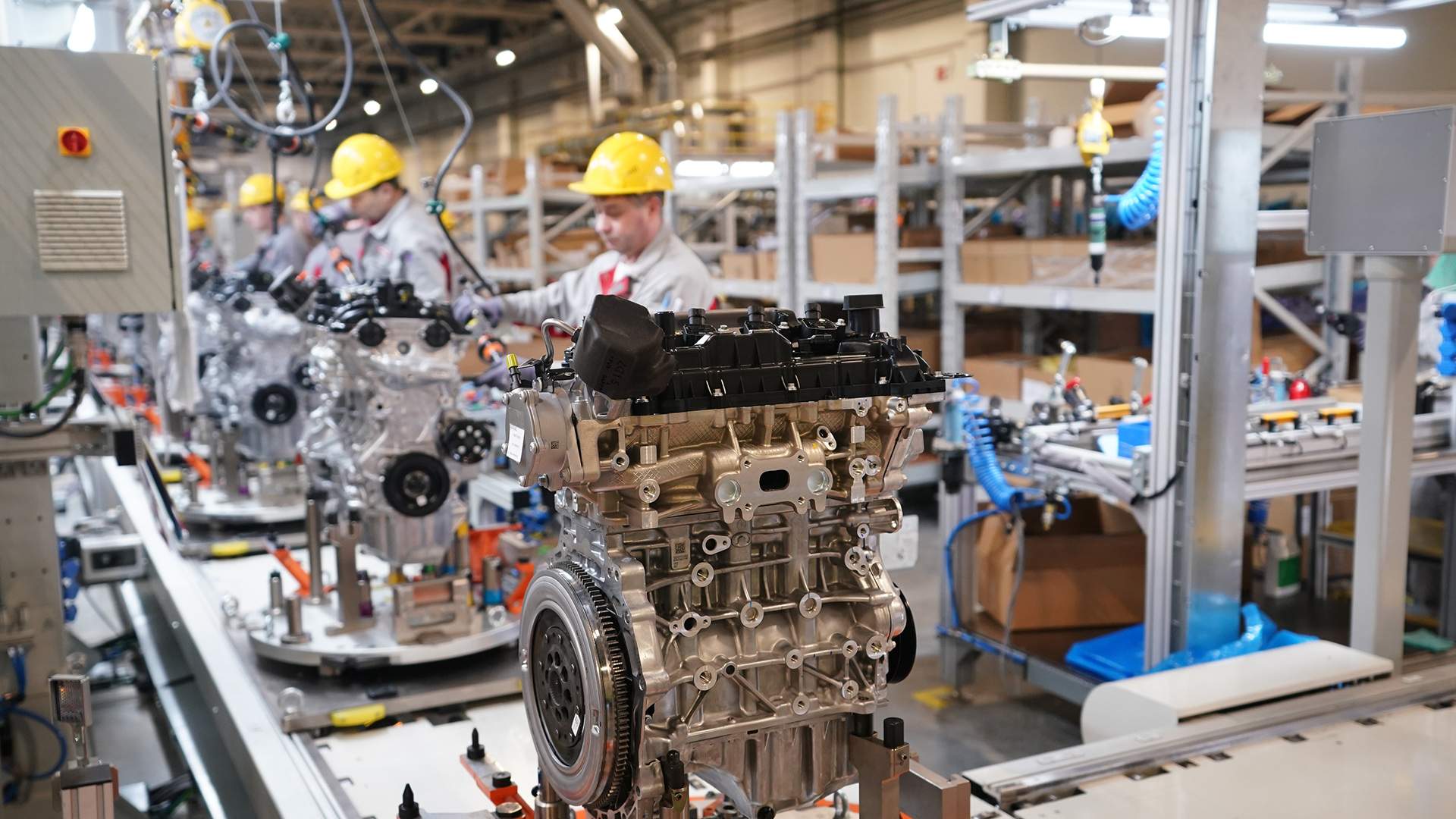

Gorchakov said that in 2022, a program was launched to provide automakers with critical components, which includes three stages. At the first stage, it was supposed to simply restart the stopped conveyors of the industry enterprises. The second one provided for the restoration of the complete vehicle configuration, taking into account ABS and airbags. The third stage of this program is currently being implemented, aimed at providing critical components for new products and models of domestic automakers.

— Within the framework of this program, we have 20 automakers, 200 manufacturers of automotive components, and 26 working groups have been formed. 90 projects have already been approved, 82 projects under the FRP line. The government pays very serious attention to the component industry. 266 billion rubles have been invested, of which 142 billion through the FRP. If at the start we had about 742 critical components fixed, then a solution was found for 326 of them. Another 416 are under study and issues with them are now being resolved through friendly countries,— said the director of the Center for Industry Analysis and Forecasting at FSUE NAMI.

"Balloon"

Localization of a domestic product becomes uncompetitive without government support, said Alexander Britz, Director of New programs at MGC Group. The point system does not stimulate the development of new technologies, he believes.

— The "balloon" from the state is what any client who comes to Russia focuses on. His goal is not to localize, but to receive subsidies and support from the state, to return it through a recycling fee, and the principles of work that he signed with the state. Unfortunately, the points and support for R&D are fading. Complex products require more time, expensive investments, and support related to engineering and laboratory upgrades," he said.

Currently, Russia has a system in which every automaker gets access to government support if they score a certain number of points and pass the barrier, Alexander Gorchakov noted.

— In this regard, the slogan "let's add points to everyone who asks" is wrong, because points can become worthless and automakers will not need them. We can already feel it. For example, access to state support in the field of passenger cars has been in effect for five years without a rise, and points are being added," he said.

SUVs, air bags, oil seals

Nevertheless, Russian automakers are actively investing in research and development.

— Electric vehicles are much simpler in terms of the component base than gasoline vehicles. We don't need an internal combustion engine, and let's face it, it's already an outdated technology. With the help of electric vehicles, we can make a leap forward in terms of technology and immediately move to a high-tech base. The electric car also attracts software developers in the first place. We have launched our own apps for Evolute and Voyah, which allow you to control cars remotely. This is a pretty serious job that has been done by our engineers," said Vasily Chebotarev, head of special projects at Evolute, at the IMAF conference.

Sollers, as follows from the presentation shown, spent over 4 billion rubles from 2022 to 2024 exclusively on R&D and development. This made it possible to apply a localized diesel engine and a mechanical transmission, not only to the Sollers model range, but also to the UAZ model range. In addition, the development of a new SUV, which will be unveiled by the end of the year, is being carried out by Russian engineers together with a technology partner. Moreover, even before the car entered the market, some of its parts began to be localized in Russia.

"The joint development gives us the rights to use the design documentation of this product to the full in Russia and the opportunity to create derivatives from this SUV under the brands of the Sollers Group," said Zoya Kaika, Deputy General Director of Sollers Group LLC.

She outlined another promising area — the production of airbags.

— From our point of view, this project is one of the key localization projects, not in terms of points, but in terms of added value. So far, the market is not saturated with manufacturers of components for security systems," Zoya Kaika said. According to her, it is planned to localize magnesium alloys for the frame and material for airbags.

Sergey Ishmenev, marketing Director of the Rezalt concern, said that until 2022, complex rubber products were imported to Russia for about $300 million per year, and 60% of these imports were absorbed by the automotive industry. Some oil seals and belts were also produced in Russia, but the quality was inferior to foreign samples, he noted.

He estimated that the volume of imports, which urgently needs to be localized, reaches 87 million dollars per year. At the same time, the domestic industry has the necessary capacities, Ishmenev believes. However, the Rezalt plant in the Moscow region, which will produce 7,000 tons of rubber products per year in a full cycle, will be able to cover only 20% of the needs of automakers, said Sergey Ishmenev.

Additional adjustment is being prepared for the points

The Ministry of Industry and Trade is preparing amendments to Resolution No. 719 concerning manufacturers of automotive components, Alexander Sedov, General Director of the Automotive Industrial Cluster of the Ulyanovsk Region, told Izvestia.

— It's not enough to demand from automakers, we should already move on to automotive components. There are many more of them, it is more complicated organizationally, while the processes of automotive components are different: some have plastic, others metal. It was necessary to reach out to such groups of automotive components and adjust the 719th resolution to the groups. NAMI plays the leading role, but, again, industry organizations have the right to vote, and you can submit your proposals for consideration. While we have a proposal for cable products, now it is simply not taken into account in the points system. The second area is software, which becomes a part of the car and is used in design and production. This is also an element of technological independence. How to take it into account is still unclear, but we need to at least collect this data," Alexander Sedov told Izvestia.

The press service of the Ministry of Industry and Trade confirmed to Izvestia that the agency is in constant contact with the industry community, in particular with manufacturers of automotive components, and together with FSUE NAMI is collecting and analyzing proposals aimed at improving the scoring.

"This work is carried out on a regular basis and is aimed at forming balanced solutions that will further stimulate the development of new technological operations and competencies," the press service noted.

They also added that a set of state support measures is provided to increase their own production of components and expand their range. These are subsidizing R&D, subsidizing reengineering costs, preferential loans under the Avtokomponents program, and a cluster investment platform.

It's a long and difficult process

The fact that the actual localization level of Russian cars is noticeably lagging behind the stated indicators is not surprising, says Maxim Kadakov, editor-in-chief of Za Rulem magazine. According to him, the parameters set out in the Automotive Industry Development Strategy were initially overestimated.

— Back in 2022, when this document was adopted, the figures recorded in it caused me great doubts. It is impossible to achieve a high level of localization at once just with a snap of the fingers and instructions from the cabinets. This is a long and difficult process that requires serious investments in technology development, equipment upgrades, and R&D," Maxim Kadakov told Izvestia.

According to him, one of the fundamental problems of the industry is not even in the very level of localization, but in its depth. Many components and assemblies manufactured in Russia are still assembled from foreign components.

— Take, for example, the paint that car manufacturers buy from Russian suppliers. Yes, the car paint or varnish itself is domestic, produced at a Russian factory. But many of the components that make up them are imported anyway. It's the same with the other parts.: one or another electronic unit is Russian, but its "insides" are supplied from "friendly countries."

The fact that the localization level is constantly changing, as well as its decrease at the beginning of this year, is nothing to worry about, says Igor Morzharetto, partner at the Autostat analytical agency. According to him, this is due to the launch of new car production projects in our country.

— It is obvious that any such project starts with a large-scale assembly of machines with a minimum share of Russian components and components. That's why the industry averages of the localization level are changing," he explained.

Переведено сервисом «Яндекс Переводчик»