- Статьи

- Science and technology

- Thick rock: scientists have found a way to increase the production of high-viscosity oil

Thick rock: scientists have found a way to increase the production of high-viscosity oil

Scientists have developed a new metal-based catalyst that significantly improves the efficiency of heavy oil production. It is difficult to extract it under normal conditions due to its high viscosity. Experiments have shown that using a new substance can reduce viscosity by 2.6 times and increase production by 69%. According to market experts, today more than 20% of the resource base of the Russian oil industry is accounted for by highly viscous and ultra-viscous raw materials. At the same time, it occupies only about 3% of the production structure. Read more about the new technology in the Izvestia article.

What is viscous oil?

Scientists from Kazan (Volga Region) Federal University (KFU), in collaboration with RITEK-Samara-Nafta and Lukoil Engineering, have created catalysts based on iron, nickel, cobalt, chromium and copper, which will increase the production of high-viscosity oil. This is the name given to heavy crude oil, a natural resource that plays an important role in the global energy sector, especially in conditions of depletion of reserves of light raw materials now widely used. According to various estimates, the total reserves of heavy oil reach 6 trillion barrels, of which 2 trillion are considered available for production, the researchers explained.

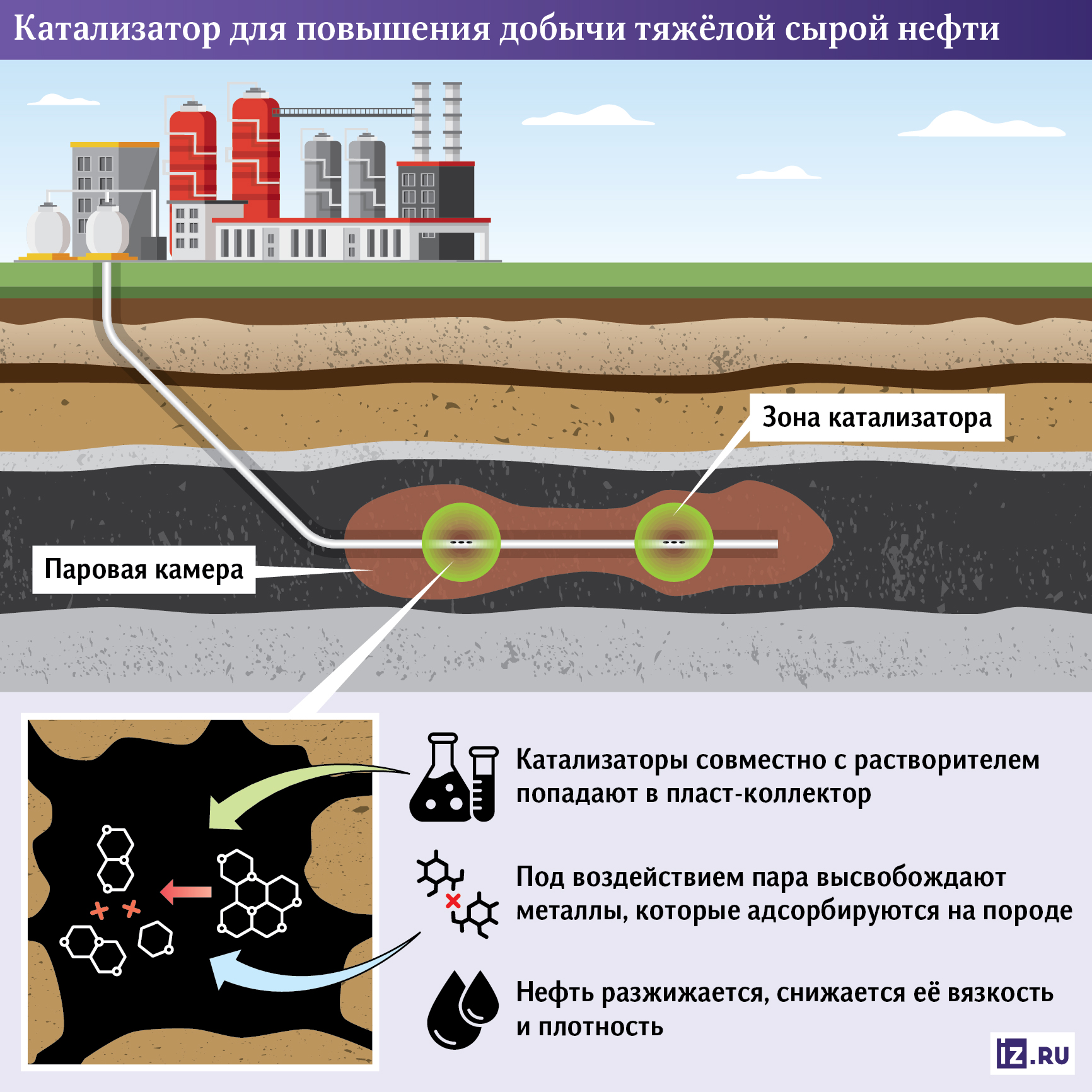

As scientists told Izvestia, the extraction and processing of high—viscosity oil is a complex process. Due to the high content of asphaltenes (heavy oil residues), resins and other organic compounds, heavy raw materials are very viscous and dense. Therefore, in order to extract it from deposits, it is necessary to use complex technologies, such as steam-thermal treatment, in which hot steam is injected into the oil reservoir, after which the oil heats up and becomes more fluid.

However, this method requires significant energy consumption and is not suitable for all types of oil reservoirs. An alternative is catalytic aquathermolysis, a method that uses catalysts to break down complex and heavy molecules in oil and turn them into lighter ones. This not only reduces the viscosity, but also improves the composition, making the raw material more suitable for further processing.

The experiment showed that a catalyst based on copper tallate, a compound of copper and tallic acid or its derivatives, reduces the viscosity of oil by 2.6 times compared with the initial samples. In addition, a catalyst based on a mixture of iron and nickel has reduced the content of high-molecular compounds, especially resins, by 8%. Iron tallate increased the content of light hydrocarbons by 17%.

As a result, the scientists chose the most suitable catalyst composition — a mixture of iron and nickel in a ratio of 85:15. The researchers tested it in the field for oil production from the well of the Aksyonov field, which is located in the Samara region. During the four months of production using a catalyst, the water content of the oil — the water content in it — decreased from 99% to 30%. High water content is a serious problem that complicates the process of cleaning raw materials, as well as leads to equipment wear, the scientists emphasized.

— We plan to continue our research to improve the composition of the catalyst and expand its field of application. In the future, this method can be used in other high—viscosity oil fields, which will make their development more economically profitable," Irek Mukhamatdinov, project manager, Candidate of Technical Sciences, senior researcher at the research laboratory of methods for increasing oil recovery at KFU, told Izvestia.

Market demand for heavy oil

As a result of using the new catalyst, oil production has increased, which shows the high efficiency of the method. In addition, the use of catalytic aquathermolysis allows not only to increase production, but also to reduce energy costs for this process. Thus, the development of a new catalyst based on metallic tallate opens up new opportunities for the extraction of highly viscous raw materials, which were previously considered difficult to access, the KFU researchers concluded.

The issue of the demand for heavy oil is rather not in the plane of demand specifically for it, but the need for fuel in general, said Nikita Zhuravlev, a consultant at the Implementation company.

— The expediency of increasing heavy oil production is due to the fact that companies at least need to maintain current production levels, but at the same time the share of traditional oil in it is steadily falling and will continue to fall, and hard-to-recover, which includes heavy oil, will grow accordingly. Oil companies simply have no other ways to maintain the necessary production levels for already explored reserves, except by putting hard—to-recover reserves into development," the expert emphasized.

All the technological developments on catalysts that our scientists currently present are very important and can be offered to Russian companies to assess the effectiveness and determine the recovery period of the well stock, taking into account the current global market conditions and geopolitical factors, Tamara Safonova, General Director of the Independent Analytical Agency for the Oil and Gas Sector (NAANS-MEDIA), commented on the development.

According to available estimates, today more than 20% of the resource base of the Russian oil industry is accounted for by high-viscosity and ultra-viscous, Valery Andrianov, associate professor at the Financial University under the Government of the Russian Federation, told Izvestia. At the same time, it occupies only about 3% of the production structure. In conditions of depletion of traditional (low-viscosity) reserves of raw materials, primarily in Western Siberia, there is a need to involve these resources in the development.

— In addition, in a number of regions, such as Tatarstan and the Komi Republic, this category accounts for a significant share of reserves and production, and therefore the effective exploitation of the relevant fields is a matter of saving jobs and maintaining the income level of regional budgets. Highly viscous oil can be used for the production of asphalt concrete, which is important due to the development of road construction in Russia. It is also possible to process it into "traditional" fuel, but this requires additional technological processes," the specialist noted.

However, in general, given the restrictions on Russian oil production as a result of the OPEC+ agreement, a significant increase in the extraction of high-viscosity raw materials cannot be called an over-urgent task, the specialist emphasized. The domestic oil industry has other opportunities to maintain and even significantly increase production. At the same time, the creation of new technologies for the extraction of these raw materials makes it possible to increase the attractiveness of this potential source.

The results of the study, supported by a grant from the Russian Science Foundation (RSF), are published in the Journal of Analytical and Applied Pyrolysis.

Переведено сервисом «Яндекс Переводчик»