Printed discovery: Transparent 3D models will show the weak points of airplanes and ships

- Статьи

- Science and technology

- Printed discovery: Transparent 3D models will show the weak points of airplanes and ships

Russian engineers have proposed a new technique for testing the strength of complex structures — elements of aircraft, buildings, turbines and other facilities. The technology consists in 3D printing of reduced or enlarged copies of parts made of transparent polymers and their testing under load. At the same time, the material from which the models are created changes its optical properties under mechanical stress, which makes it possible to visualize internal stresses and weaknesses of the structure. Development may also be required to verify the accuracy of design programs.

How 3D models and light reveal structural weaknesses

Engineers at the Moscow Aviation Institute (MAI) have developed an advanced technique for studying structural strength. It involves 3D printing of scaled-down copies of the studied elements from transparent composites and their testing under loads. At the same time, the weak and vulnerable points of the structure are visualized.

The development is designed to calculate, at the design stage, the permissible load on critical aircraft parts: the wing, fuselage, or engine parts. The solution is also suitable for testing the strength of elements of buildings, monuments, ships, turbines of power plants and other complex technical facilities that experience significant loads during operation.

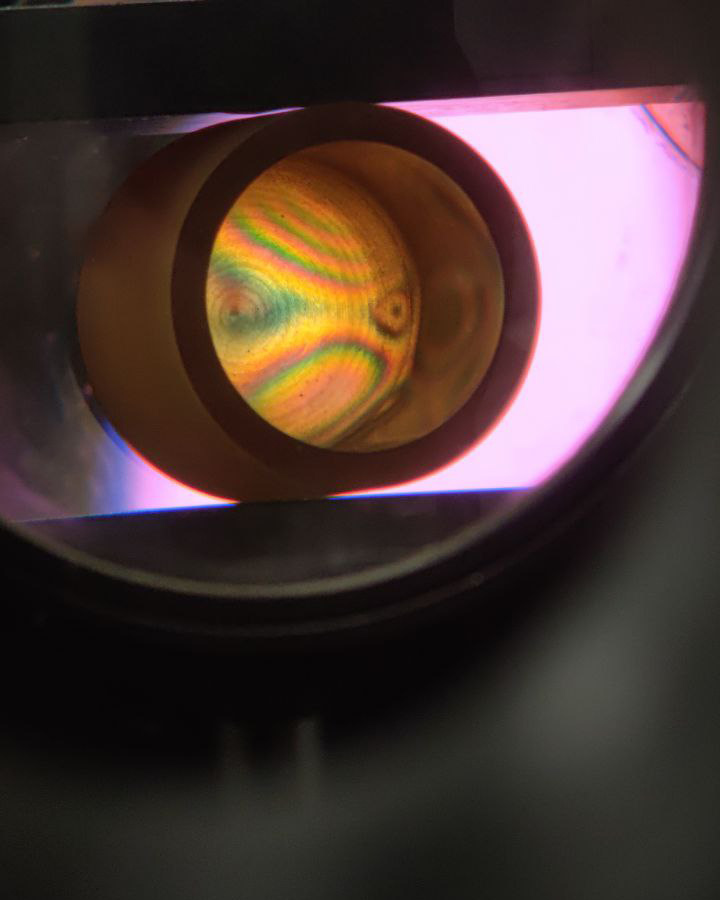

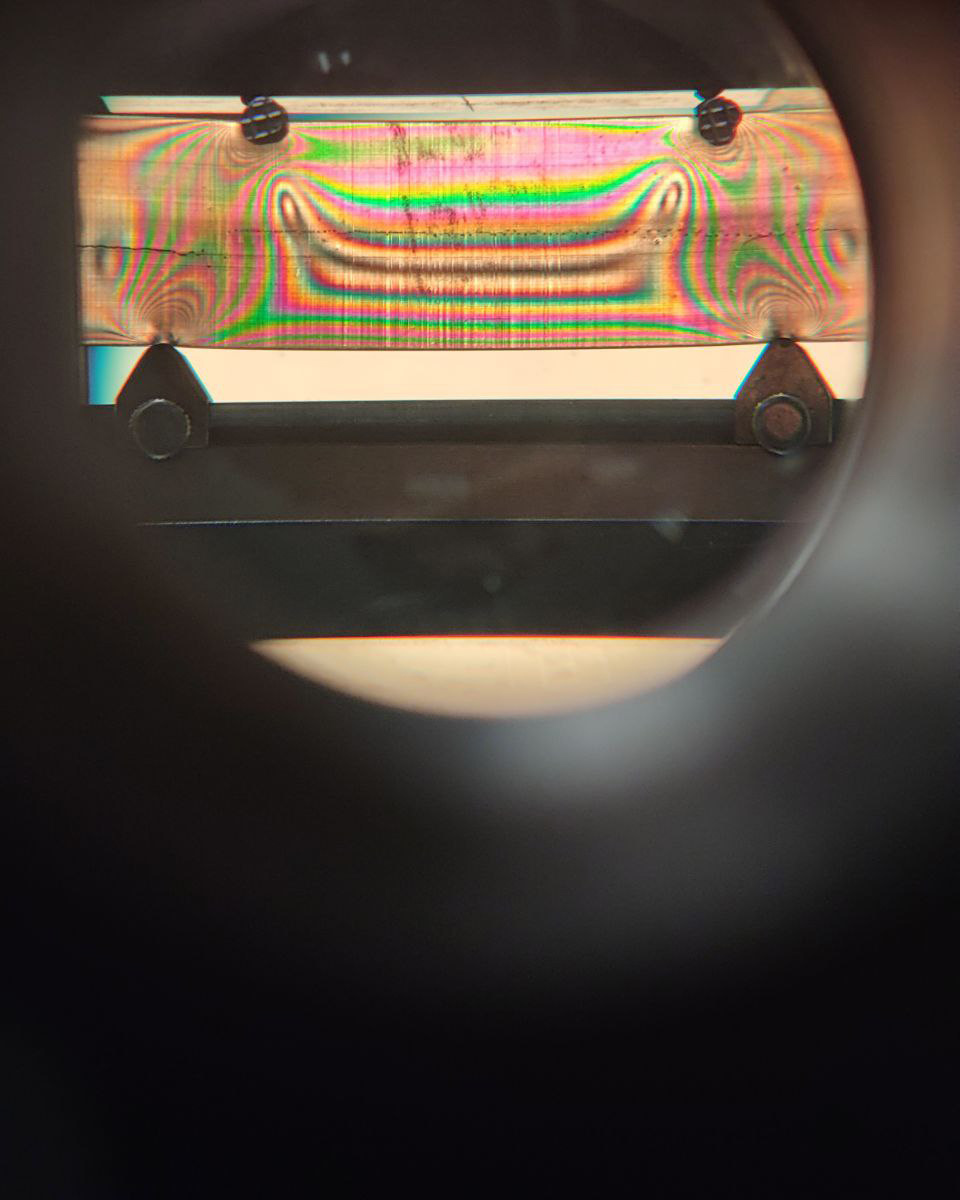

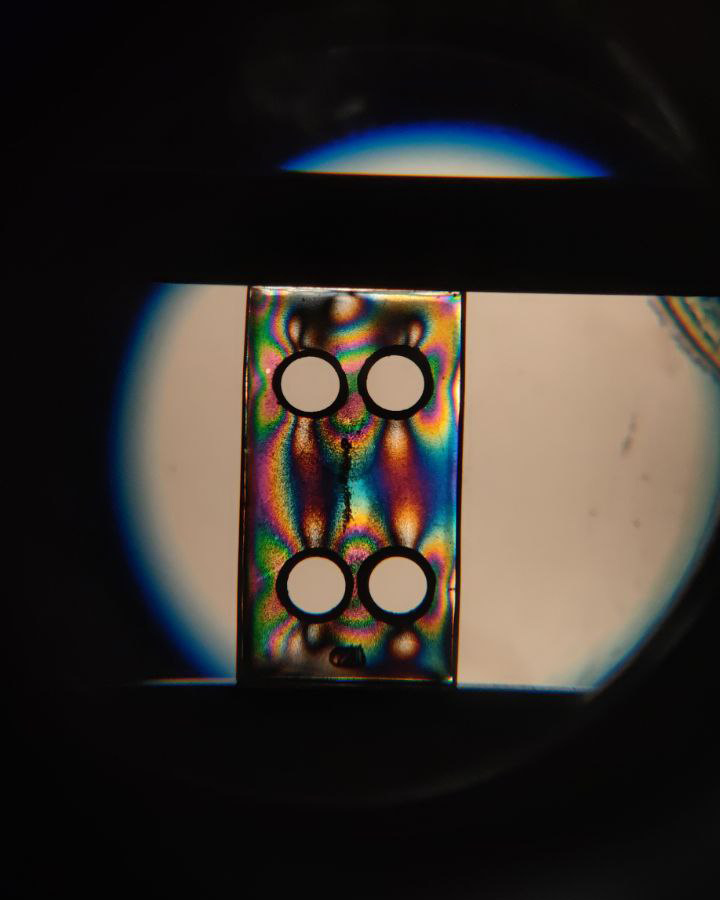

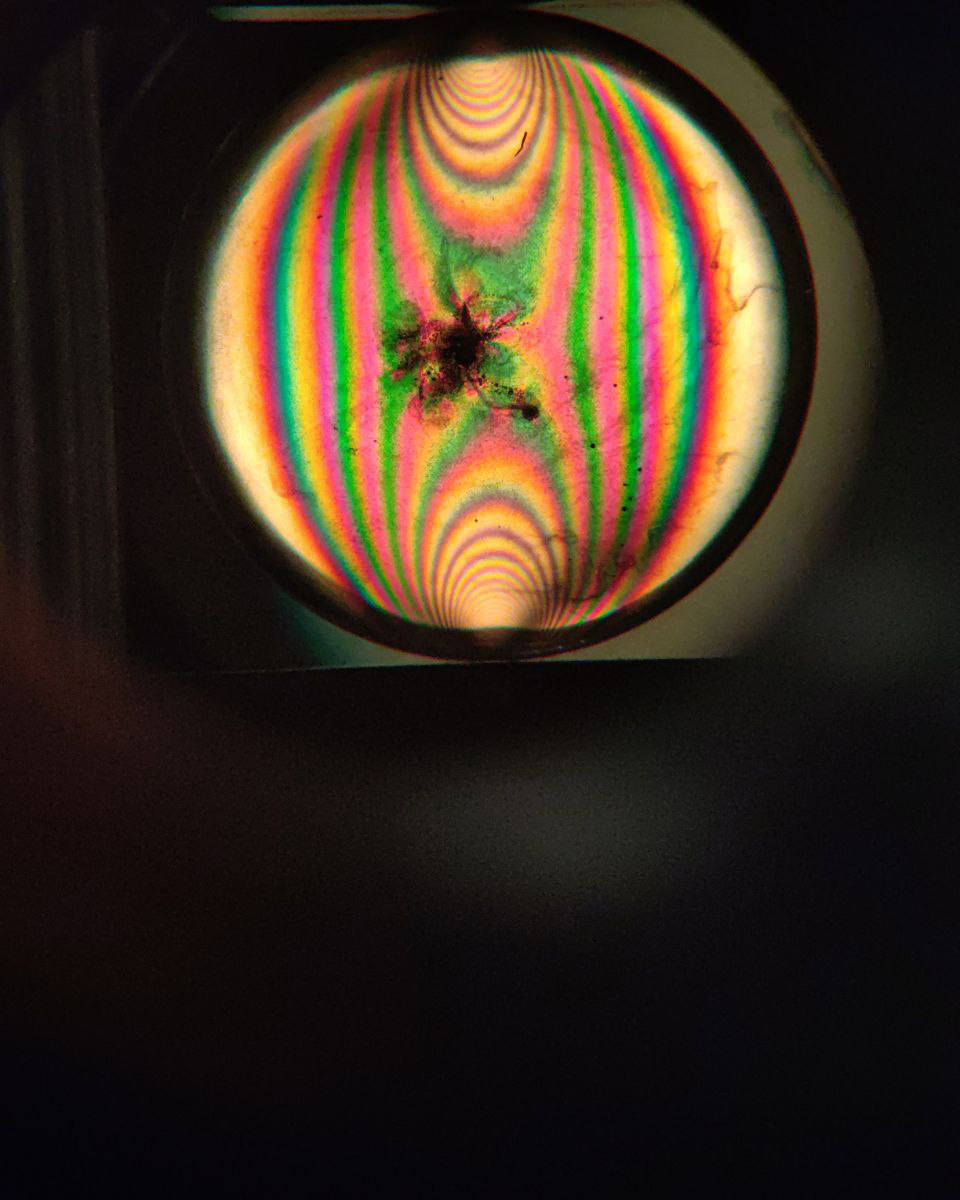

— The technique involves creating experimental models on a 3D printer - reduced or enlarged geometrically similar copies of parts, the strength of which we want to test. Transparent polymers are used as the material, which change their optical properties under mechanical stress, which makes it possible to see how loads are distributed inside the samples," said Roman Sabitov, one of the developers, an engineer and graduate student at the Department 203 "Engine Design and Engineering" at MAI.

According to him, if you illuminate the details with polarized light, characteristic color stripes appear in them, which reflect the picture of internal stresses. A thermal imager works by a similar principle. Only it is not the temperature that is being investigated, but the mechanical loads.

The proposed approach allows designers to quickly identify the loaded zones of the objects under study and, if necessary, adjust their shape in such a way as to increase their resistance to destruction, the scientist explained. The development combines modern 3D printing technologies and the traditional experimental method of photoelasticity, which is based on changing the optical properties of a transparent material under force action on it.

— Previously, epoxy resin casting was used to produce experimental models. They were heated, and then poured into molds and waited for solidification, which took weeks. At the same time, any mistake entailed stopping the process and redoing it from scratch. Now, thanks to 3D printing, it takes several hours to prepare a model. This makes experiments more reliable and flexible," said Roman Sabitov.

At the same time, the new technique allows you to create and check complex geometric details. It also allows you to model the internal anisotropy (heterogeneity) of materials. This makes the experiments more realistic, he added.

How the analog method helps to verify digital solutions

At the same time, the proposed approach makes it possible to verify the correctness of computational models by comparing the results with field experiments, the expert noted. Thus, a significant area of application of the development may be testing programs for structural calculation and strength analysis.

— For example, in computer modeling of a structure, you need to build a finite element grid before calculating it. And in the construction of its nodes, an error often creeps in, which, according to some data, can reach 20-30%. In contrast to such approaches, the photoelasticity method is analog. It allows you to visually see a picture of the voltage distribution, free from computational errors and approximations," explained Roman Sabitov.

This is important because foreign companies that provide software for engineering analysis, such as ANSYS and Siemens NX, have left the Russian market. They are being replaced by domestic solutions that require careful verification, he stressed.

Currently, in order to further develop the technology, developers are exploring more transparent polymers and developing algorithms for automatic analysis of the stress patterns obtained, the scientist added. Specialists are also creating a new test stand.

— The method opens up prospects for quick and inexpensive verification of design solutions. Its advantages include the easy and fast production of a model thanks to 3D printing, the ability to create structures of a very complex shape," Oleg Panteleev, aviation expert and executive director of the Aviport agency, told Izvestia.

At the same time, in his opinion, the approach does not eliminate the need for field tests of structures in the form in which the product will be mass-produced, but, on the other hand, the proposed methodology can speed up the design and refinement stages.

At the same time, there is a lot of work ahead to confirm the reliability of the technology and assess its applicability, the expert stressed.

— The innovativeness of the development is applied and methodical in nature. This is an example where existing approaches, when combined, generate a qualitatively new tool. In particular, the ability to quickly create complex geometric shapes with specified properties opens a new chapter in experimental mechanics, where step—by-step testing and modification of structures turn from an expensive exception into a standard practice," said Alexey Adamovich, Director of the Research Institute of Building Materials and Technologies at the National Research University of Moscow State Technical University.

The development contains the potential for improvements and development. For example, by adding smart materials to the polymer matrix. In particular, sensor particles with selective sensitivity to temperature influences or to different types of loads (such as shear or torsion). They will allow not only to visualize stresses, but also to determine the nature of loads and track the accumulation of fatigue damage, the expert concluded.

Переведено сервисом «Яндекс Переводчик»