Base shift: Russia has created a universal engine for drones

A universal electric motor for drones with propellers was created in Russia. When finalized, the power units will be suitable for land or surface devices, the authors of the project told Izvestia. The product consists mainly of domestic components and is comparable in price—quality ratio to its Chinese counterparts. Serial production of the engines is planned to be launched within a year. However, in order to manufacture fully import-substituted engines, it is necessary to develop domestic mining and processing of rare earth metals, production of magnets and microelectronics, experts noted.

How electric motors work

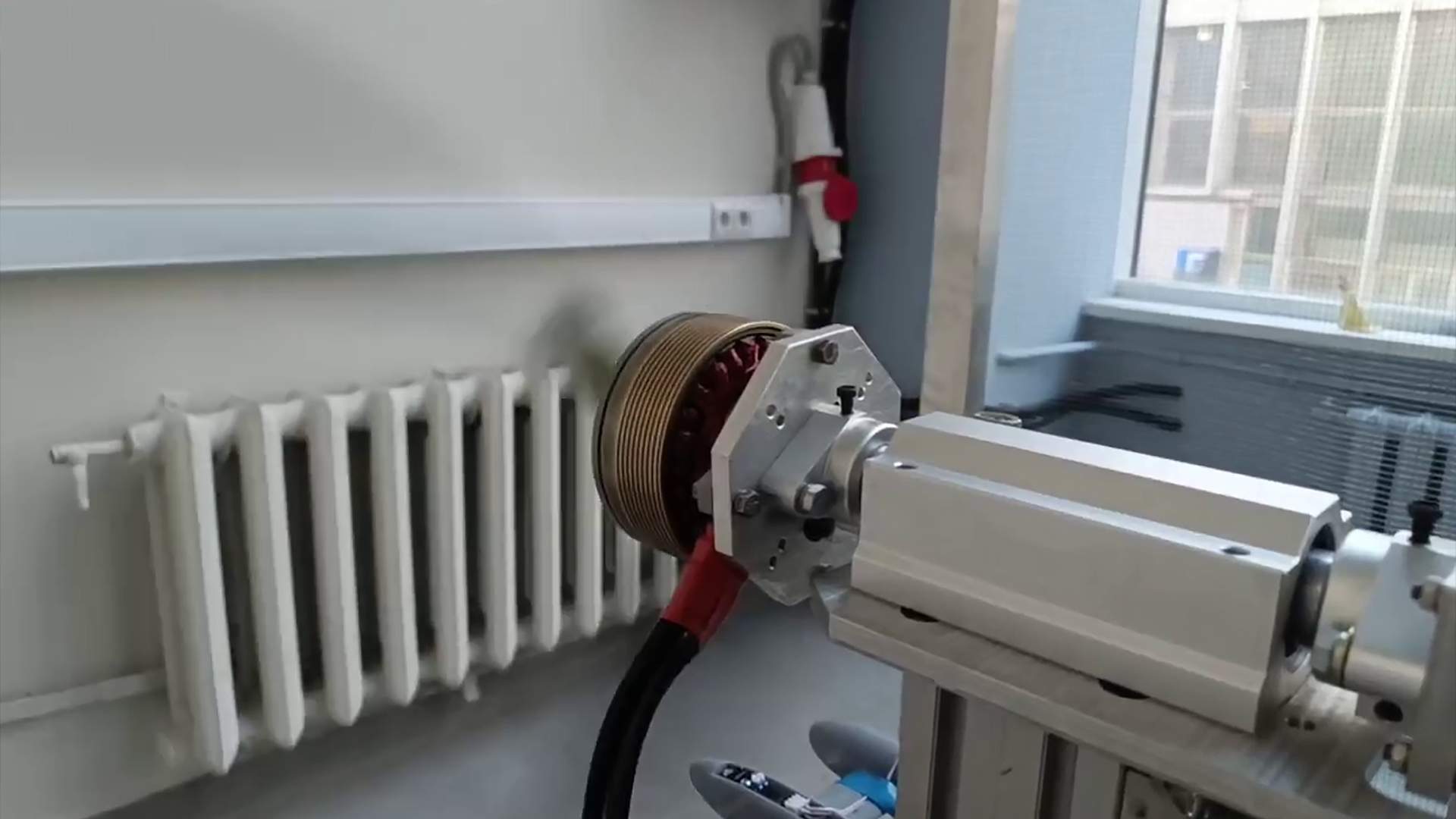

Scientists at the advanced engineering school of the Moscow Aviation Institute (MAI) have developed a new electric motor for heavy unmanned aerial vehicles. It has versatility and can be equipped with various types of drones with a helical group, both copters and gliders. With a little modification, it can also be installed on land and surface vehicles.

According to the developers, the engine consists almost entirely of domestic components. The only magnets produced abroad are magnets that are not currently manufactured in Russia. According to calculations, when mass production is launched, the domestic power unit in its class will be able to compete with its Chinese counterparts, which now occupy the vast majority of the market for such devices in our country.

— Electric motors are mainly produced in China. However, at a comparable cost, the development of MAI has better material quality and higher mass-energy indicators. In particular, at a rotational speed of 6800 revolutions per minute, the engine can provide long—term power of up to 12-13 kW and short—term power of up to 16 kW," Nikolai Ivanov, head of the Research Department of the Department of Electric Power, Electromechanical and Biotechnical Systems at MAI, told Izvestia.

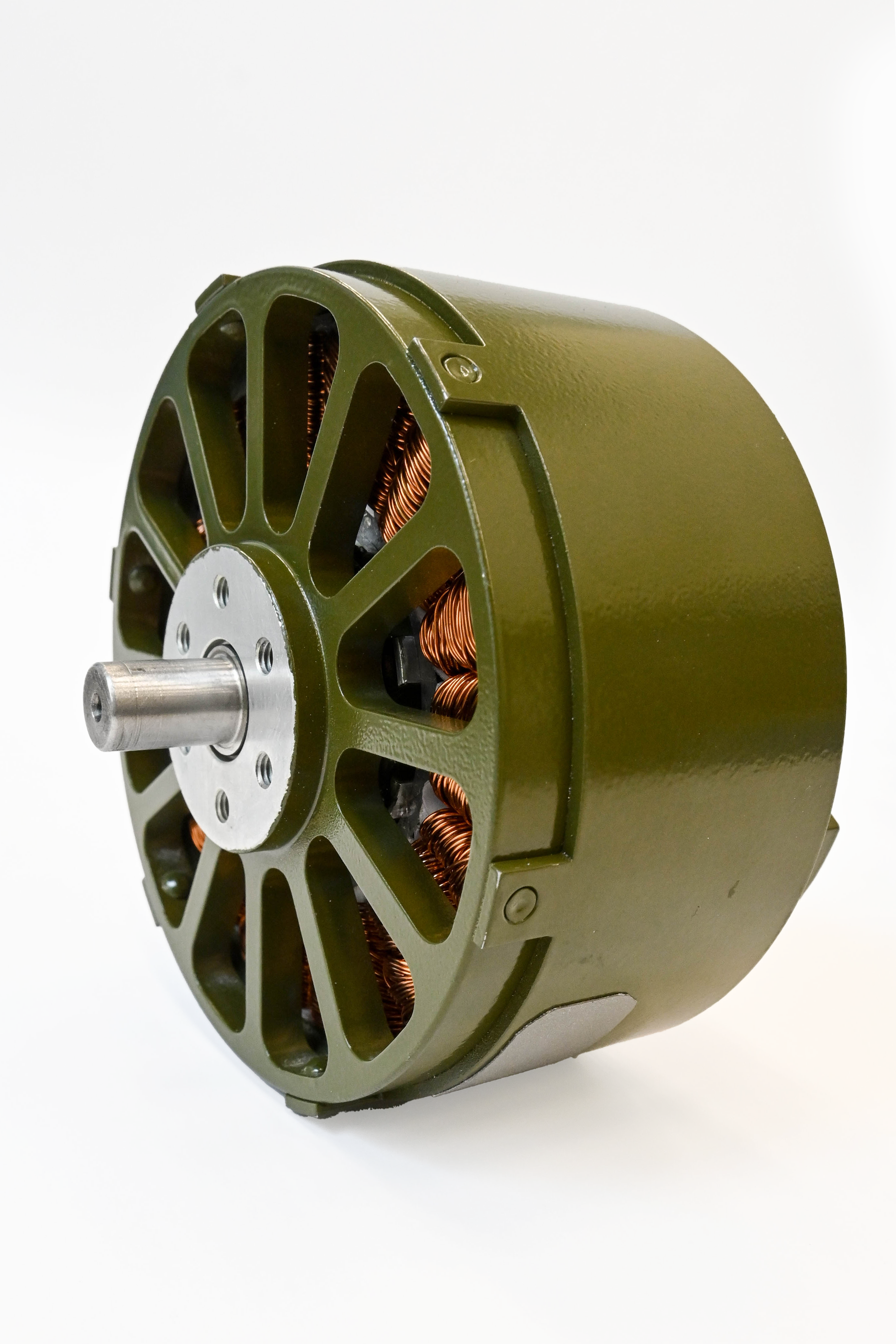

According to him, it was possible to increase the characteristics of the product due to the author's computational modeling techniques. With their help, the developers have identified the most rational ways in which the magnetic flux closes in the engine. Due to this, in some cases, efficiency gains can reach 10%.

As the scientist explained, the magnetic circuit of the power plant includes elements such as a stator, rotor, permanent magnets, as well as air gaps between them. If the geometry and location of these components are optimally selected, the magnetic flux does not "leak" beyond the useful area (for example, through the motor housing), but is evenly distributed inside. This reduces energy dissipation losses and increases the efficiency of its conversion into work.

The thrust generated by the electric motor depends on the power of the electric motor, the developer explained. Increasing this resource will allow manufacturers to increase the speed, carrying capacity or maneuverability of drones.

— Today in Russia, similar power units are being developed only for specific devices and specific customers, and there are no available domestic solutions on the free market. Based on this, experts have developed a solution that can be used in various types of unmanned devices. The weight of such devices can range from 30 to 120 kg, depending on the number of engines," explained Nikolai Ivanov.

What technologies are needed for import substitution

The products withstood the required test cycle, and testing was performed on specialized stands for propeller-driven groups, the scientist said. The second stage of the tests took place at the MAI airfield in Alferevo, a full—fledged aviation base with its own airspace.

According to Nikolai Ivanov, a control unit and the corresponding software are being created complete with the engine. During the year, the developers plan to enter mass production.

— The development of MAI is an improvement and modification of already known types of engines, but the very attempt to establish their production in Russia is important. After all, now Chinese analogues are usually purchased in the country," said Alexander Zaitsev, Associate Professor of the Department of Aviation Technology Operations at Samara Korolev University.

At the same time, he added, most modern electric motors are brushless. That is, in them, the rotor rotates using an alternating magnetic field, which eliminates physical contact between the stationary and rotating parts. This makes the power units more durable and efficient. However, it is worth noting that our country does not have its own production of magnets, and the extraction of rare earth metals, which are necessary in their manufacture, has been monopolized by China. Therefore, in order to achieve true competitiveness, it is also necessary to establish the entire chain, starting from rare earths and magnetic materials.

According to the expert, other difficulties that developers may face include the lack of a well-established engine design methodology. Such calculations are carried out approximately, and then refined using software modeling tools. In addition, high-speed motors face problems with vibration of the stator plates. They can fluctuate with the frequency of the current flowing in the stator windings, which can lead to resonance and destruction of the motor. These physical phenomena are also difficult to account for.

— A brushless motor needs a controller. This is a chip board that switches the current in the magnetic coils so that the motor turns. Companies that report their own engine production "forget" to mention where they purchase the controllers. And this is a separate complicated story," added Dmitry Kuzyakin, Director General of the Central Research Institute.

For example, a conventional FPV drone has four engines and each needs its own controller, the expert explained. Each controller has a microprocessor and a program that controls the motor, without which it simply won't spin. Making the engine itself is half the battle, but creating a controller for it is already much more difficult. To produce them, we need to develop our own microelectronics, the expert concluded.

Переведено сервисом «Яндекс Переводчик»