- Статьи

- Science and technology

- Calculate all waste: smart optical garbage sorter created in the Russian Federation

Calculate all waste: smart optical garbage sorter created in the Russian Federation

Russia has developed a prototype of a smart optical garbage sorter that knows how to sort waste itself. The apparatus not only recognizes the shape and color of an object, but also determines what material they are made of, since objects made of different components can look the same. According to the developers, the technology will allow to extract at least 5 million tons of glass, paper, plastic, and metal from 60 million tons of solid municipal waste, which are generated in the country annually.

What is an optical garbage separator

Specialists of the NTI Competence Center "Wireless Communication Technologies and the Internet of Things" on the basis of Skoltech have developed a smart device that can annually extract millions of tons of useful resources (plastic, glass, paper, etc.) from the household waste of Russians. This was reported to Izvestia in the press service of the Foundation for support of NTI projects. The apparatus should replace the flagship imported separators, which are difficult to import into the Russian Federation.

According to the developers, the country generates 60 million tons of solid municipal waste annually. At least 5 million tons of glass, paper, plastic and metal can be extracted from them every year. But there are a number of problems that do not allow achieving such volumes.

- Even separately collected waste is subject to additional sorting, it must be sorted by class and color," Anton Stepanov, a research engineer at the NTI Competence Center "Wireless Communications and Internet of Things Technologies" based at Skoltech, told Izvestia. - At a large waste sorting complex, an average of 3 tons of plastics are carried on the conveyor belt per hour, and one worker takes away only 40 kg of film and 100 kg of plastic bottles during the same hour.

At the same time it is almost unrealistic to put the right number of people for sorting. Because of this, a huge share of secondary raw materials is lost, the developers explained.

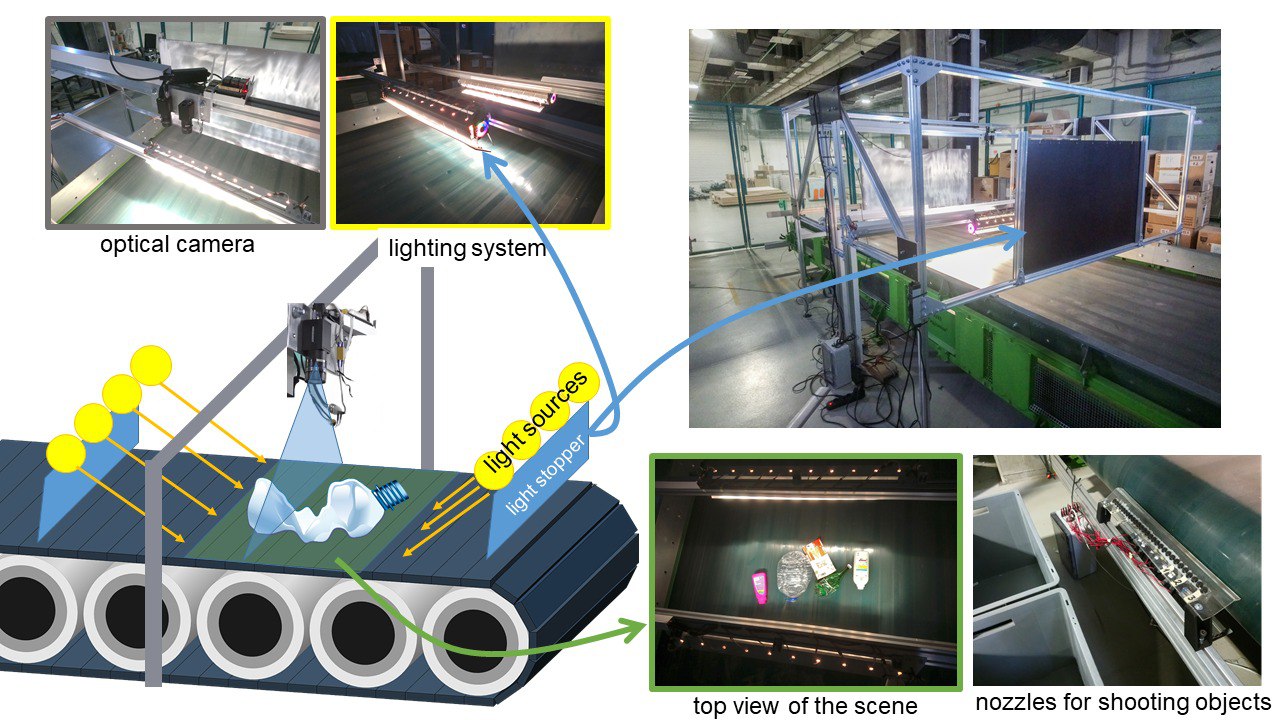

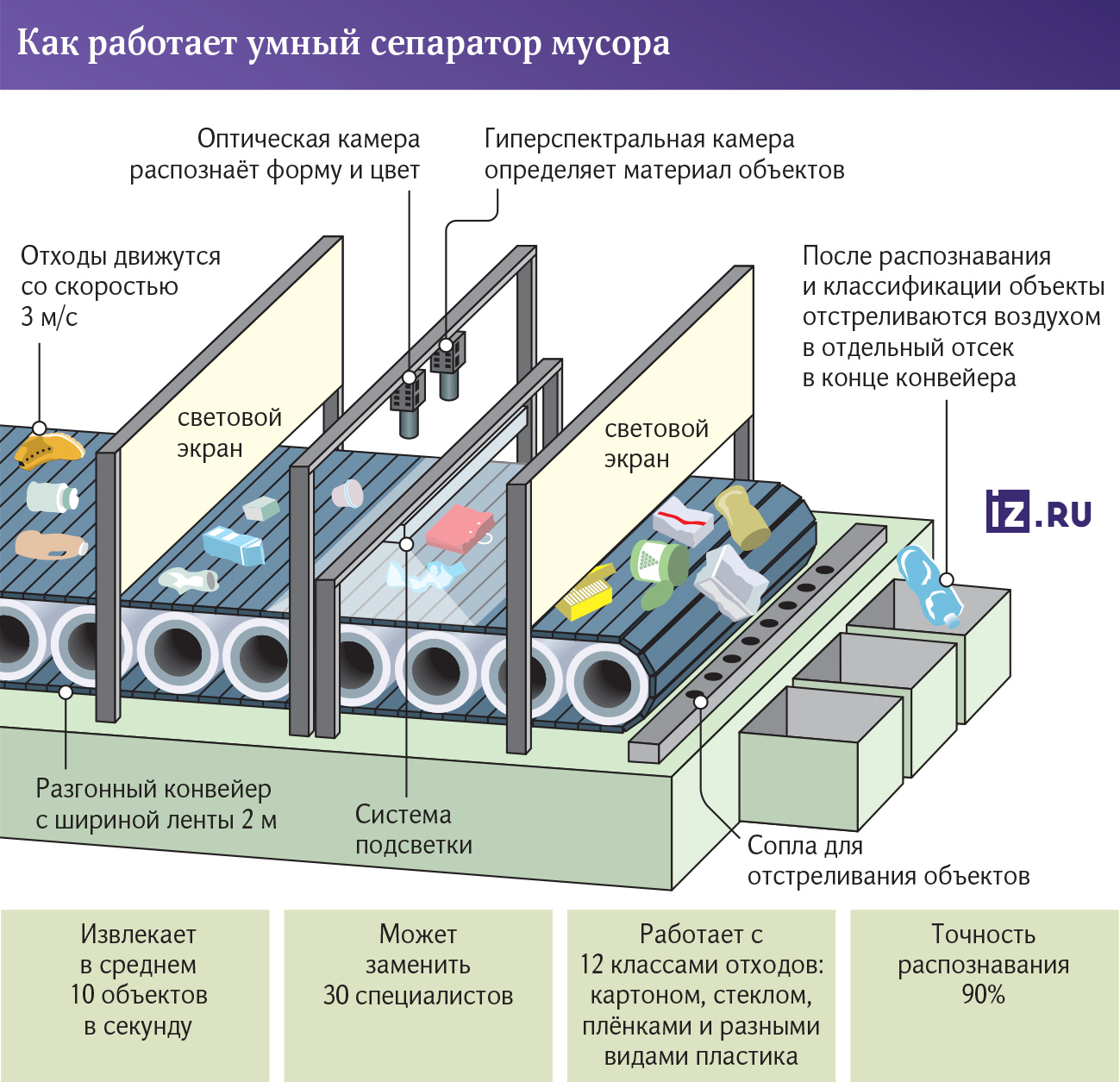

To solve these problems, the developers have created a prototype of a smart sorting machine, which alone can replace 30 specialists. The optical sorter extracts an average of 10 objects per second. It includes an accelerating conveyor with a belt width of 2 meters, on which the waste moves (at a speed of 3 m/s), a system of illumination in the area of camera installation, as well as two cameras - optical and hyperspectral. They are responsible for scanning the garbage.

How the smart garbage separator works

The separator not only detects shape and color (the optical camera does this). The hyperspectral infrared camera helps to identify the material of objects, as objects made of different materials can look the same. The recognition accuracy is 90%. Now the separator works with 12 classes of waste: cardboard, glass, films and different types of plastic.

The brain of the separator is a recognition and classification system that detects the position of useful fractions using computer vision in no more than one second. Such fractions, after being analyzed, are blasted away by air into a separate compartment at the end of the conveyor belt.

A group of Skoltech scientists has also developed a method for recognizing labels and brands on objects moving along the conveyor belt. This is necessary for more accurate sorting and statistical accounting, explained graduate student Sergei Nesteruk.

- The problem of many researchers is that they solve the problem in conditions far from industrial requirements and infrastructure, and then cannot scale the development, - said "Izvestia" project leader, Professor of Skoltech Andrei Somov. - Having such a separator, we will be able to develop waste processing in our country at the proper level.

Development of industrial sorting of garbage

The technology of industrial sorting was developed back in the 1930s, at that time it concerned agricultural products, Sergei Kosogor, head of the "Smart Supply Chains" segment of the FoodNet (Foodnet) NTI working group, told Izvestia. Over time, the approaches of optical waste sorting have changed.

- Taking into account the energy efficiency of the development, it is worth analyzing the saving of resources (metals, plastic and paper, etc.), reduction of labor costs, reduction of environmental impact. In general, the project is very promising," said the expert.

The first optical separation systems appeared in Europe in the 2000s, which was facilitated by very strict recycling requirements. The technology of such separation is being implemented at waste sorting complexes in Russia as well. For example, in Novokuznetsk at the EcoLand landfill. Mostly foreign robotic systems are used, which thanks to modern equipment and advanced algorithms are able to recognize different types of waste in the stream with high accuracy and speed, said Varvara Mikheeva, ecologist and program director of "Boiling Point - Novokuznetsk". This makes it possible to effectively separate valuable fractions of recyclable materials, such as plastic, paper, metal, glass and others, from the general garbage.

- The development of waste sorting technologies in Russia is promoted by the national project "Ecology", which sets an ambitious goal of achieving 100% waste sorting by 2030. These initiatives not only contribute to improving the environmental situation, but also open new opportunities for domestic manufacturers of equipment and software, stimulating the development of domestic technological solutions in this area," she said.

The quality of recycled material is strongly influenced by the type of waste collected. For example, labels and even glue on the surface of a bottle can pose a big problem that makes recycling more expensive, said Evgeny Alexandrov, acting director of the Center for STI Digital Materials Science at Bauman Moscow State Technical University.

- Therefore, it is important to sort even bottles into different waste classes. Such labor is very routine and unattractive, which is why automation is necessary," the expert added.

This year, the NTI Competence Center based at Skoltech plans to conduct a pilot launch of the separator at one of the recycling plants in Russia.

Переведено сервисом «Яндекс Переводчик»