- Статьи

- Science and technology

- Printer races: a robotic arm has been taught to print cartilage and tissue on a patient's body

Printer races: a robotic arm has been taught to print cartilage and tissue on a patient's body

Roboruka will print customized bioimplants right during surgeries. Russian scientists have supplemented the existing technology with a unique modular attachment - a "brush" that can reproduce cartilage and soft tissues. This is possible both in laboratory conditions and directly on the patient. Read more about the approach, which opens new horizons in the treatment of complex and extensive burns, ulcers and other tissue damage, read in the material "Izvestia".

Roboruka will print cartilage and tissue

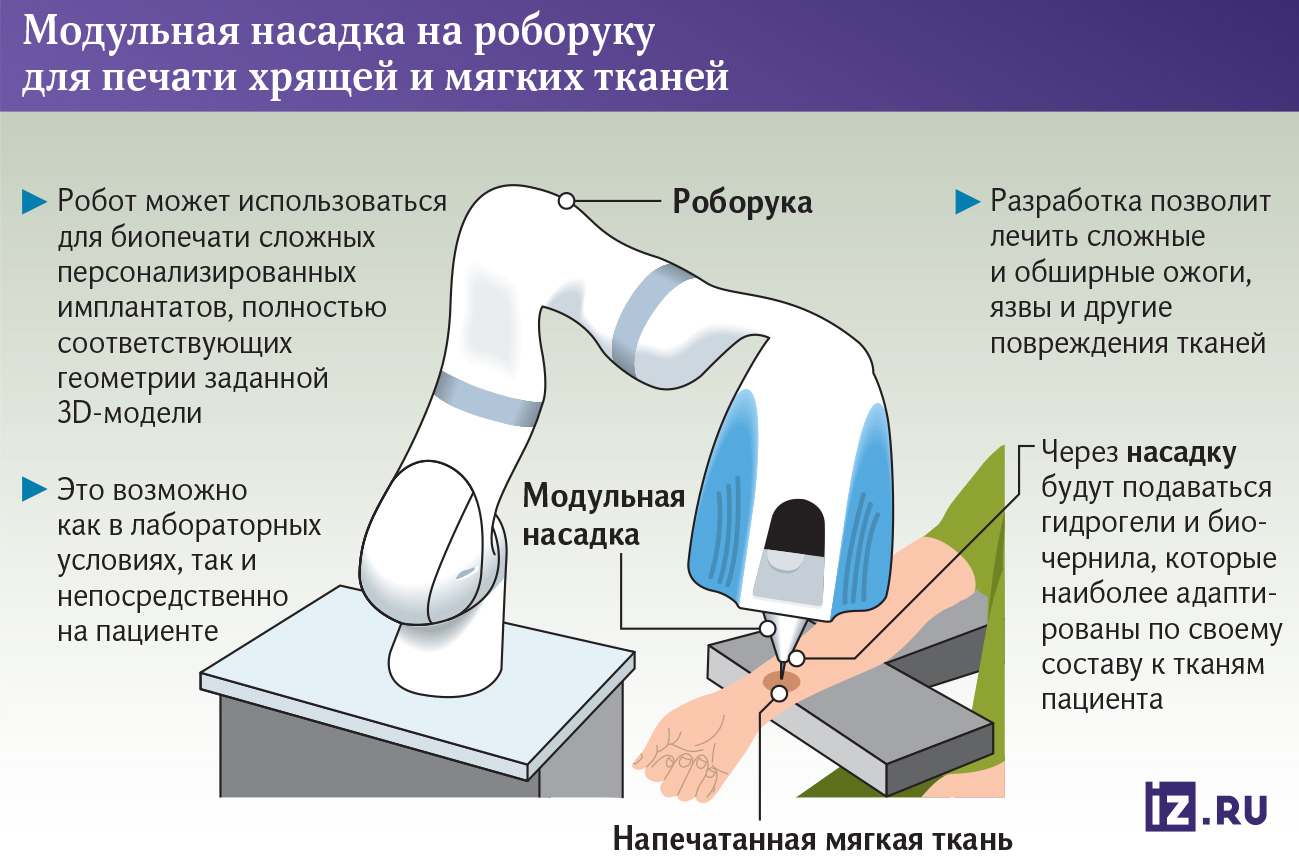

Scientists of the Center of Competence NTI on the basis of Samara State Medical University (SamSMU) together with scientists of NITU MISIS have developed a modular attachment to the roborouka, which will allow printing cartilage and soft tissues, including during surgery directly on the patient.

- We planned to adapt the roborouka to create bioengineered structures and personalized implants by bioprinting tissues directly on the patient when treating extensive burns, ulcers and other injuries. Now, thanks to the developed attachment, this will be possible," Larisa Volova, head of the Center for Biomedical Cellular Products of the Center for STI Bionic Engineering in Medicine at SamSMU and director of the BioTech Research Institute, told Izvestia Larisa Volova.

The university's bioprinter park was replenished with a robot arm back in November 2023. It is designed to solve problems in the field of biofabrication and 3D-bioprinting, including the creation of bioprinted skin and hyaline articular cartilage bioanalogs. To date, no such robots have been produced in the country.

Hydrogels and bioinks, which are most adapted in their composition to the patient's tissues, will be fed through the developed nozzle. For these purposes, the Research Institute "BioTech" SamSMU has developed its own hydrogel from bioimplants obtained using the original technology.

- The robot can be used as a high-tech device for bioprinting complex personalized implants that fully correspond to the geometry of a given 3D model. This is possible both in the laboratory and directly on the patient. During the operation, the robotic arm's movements are synchronized with the biomaterial supply, taking into account body movements such as breathing. This approach opens up new horizons in the treatment of complex and extensive burns, ulcers and other tissue damage," said Nikolay Ryabov, head of the Bioprinting Laboratory of the BioTech Research Institute Nikolay Ryabov.

Introduction of robot arm with bioprinter into practice

The way of introducing such developments into clinical practice is long, so it is important to move in this direction together. Thus, NITU MISIS acts as a coordinator of the consortium "Health Engineering", which includes scientific centers, medical organizations, industrial release sites, Fedor Senatov, Doctor of Physical and Mathematical Sciences, Director of the Institute of Biomedical Engineering of the National Research Institute, told Izvestia.

- Within this format, we cooperate with colleagues from SamSMU. We have strong engineering and material science competencies that allow us to successfully create advanced bioprinting systems. Earlier, MISIS together with 3D Bioprinting Solutions developed a hardware and software system for in situ bioprinting: scanning and bioprinting system and software. With its help a year ago, the world's first human bioprinting operation was performed at the N.N. Burdenko Hospital. N.N. Burdenko Hospital," he noted.

The development of 3D bioprinting technologies is extremely important for the development of domestic regenerative medicine and surgery. World trends show that the creation of implants by additive technologies and robotic tools is the future, said Andrey Lomonosov, deputy head of the NTI HealthNet working group in the direction of "Biomedicine", scientific consultant of JSC "R-Pharm".

- The technology will be in demand, as it has a number of advantages, such as the accuracy of the implants created, accelerating healing and reducing the recovery time of patients with severe injuries. And with the help of 3D printing it will be possible to create non-regenerating elements of organs and tissues, such as cartilage," he added.

The bioprinting machines that are currently used are usually stationary, said Mikhail Bolkov, a senior researcher at the Institute of Immunology and Physiology of the Ural Branch of the Russian Academy of Sciences.

- If it is possible to print with a robotic arm, this is, of course, very cool. But we need to see that all this is worked out in detail, because after all, we are talking about a living person. But in general, this is the beginning of a new high-tech era," he said.

Bioprinting technology is an extremely promising area that can significantly change the approach to the treatment of different organs and tissues. However, a number of technical and regulatory issues will need to be resolved for widespread implementation, said Albert Rizvanov, head of the Center of Excellence "Personalized Medicine" at Kazan (Volga Region) Federal University, corresponding member of the Academy of Sciences of the Republic of Tatarstan.

- There are also technical difficulties, such as the high cost of the equipment and the need for very precise adjustment of the robot arm. Another problem is related specifically to biocohernils, so that they would be biocompatible, have the necessary mechanical properties and support cell survival," the expert noted.

According to the expert, developments in this area are already underway at a good enough level and soon we will be able to see their effectiveness and significance in real practice. However, as experts note, it is necessary to make sure that the application of the technology is safe for patients.