"The industry has all the conditions for active development"

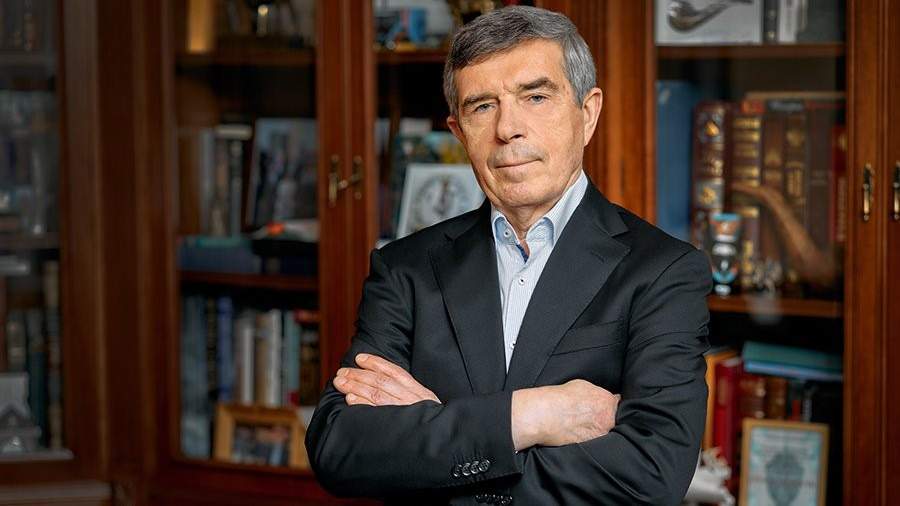

The new challenges that Russia has faced in recent years could not but affect large-scale investment projects being implemented in the country. In the current geopolitical realities, the issues of compliance with planned construction deadlines come to the forefront, as they directly affect the socio-economic development of the state and ensuring technological sovereignty. Anatoly Isaikin, Chairman of the Board of Directors of the company, told Izvestia about the changes that have occurred in the industry and new priorities in the activities of JSC Security Control Technologies (TCB.RF).

- Thanks to the import substitution course, the Russian economy received a new impetus. How do you assess the current situation from the point of view of the task set by the President to ensure industrial sovereignty?

- Many industries, of course, are experiencing some difficulties today due to Western sanctions. But in general, industry has all the conditions for active development. This is also thanks to government support. This includes stimulating measures, such as, for example, industrial mortgages, an updated regime for industrial clusters, preferential loans for the rapid launch of projects for the production of priority products, and tax incentives for buyers of Russian high-tech equipment.

A good example is the construction of technoparks in Moscow. The capital's government provides land for construction, helps to build production facilities, and also subsidizes the bank credit rate, giving businesses the opportunity to work on those programs that the city is interested in. At the same time, the land rent is only 0.01% of the cadastral value, the regional profit tax is reduced, and the property tax rate is zeroed. And the city gets additional jobs and long-term investments in the development of industry and science, development of new products.

At the same time, we should more actively develop technological partnerships with companies from friendly countries, and for this purpose we should pay attention to the customs regulation, which does not always allow to realize production inside the country.

- Your company specializes in the design and support of construction of complex industrial and infrastructure facilities, as well as industrial and environmental safety. What difficulties does your business face today? Has the focus of your work shifted?

- The policy of industrial sovereignty has encountered many barriers, both bureaucratic and applied. It is no secret that Western technologies were used in design solutions for the most part. After foreign companies left, we faced the loss of access to them. Of course, there is a substitute for them. For example, in terms of a number of characteristics, Chinese technology is not only equal to, but even superior to Western solutions. But the problem is that the replacement of technologies requires changes in project documentation, which causes time delays and additional financial costs.

Engineering should also be mentioned: this year the head of state signed a law on stimulating the development of engineering services. And in the field of industrial safety we cannot but mention the acute problem of drone attacks on fuel and energy facilities.

We should pay tribute to our specialists. They have the competence to realize all stages of construction and operation of industrial enterprises. TCB.RF engages all possible resources, minimizes potential risks and does not stop looking for new opportunities in the current situation.

- To what extent has the provision of such services become more complicated given the current sanctions?

- Unfriendly countries are tightening the screws wherever possible. Even the usual business processes with our Chinese partners are not always without difficulties. There are problems with payments, logistics, and the sanctions pressure on companies is still in place. In the field of design, the purchase of new equipment has also become more complicated.

- You mentioned imports. Can you tell us about the specifics with regard to the mining and industrial sectors?

- Back in 2009, a government decree was adopted to zero VAT on technological equipment, the analogs of which are not produced in the Russian Federation. But against the backdrop of a difficult geopolitical situation, the procedure for classifying goods when moving them across the customs border of the Eurasian Economic Union became more complicated. Russia tried to simplify the procedure and make imports more favorable for business.

At the same time, industry is in dire need of new equipment, as the existing equipment is gradually beginning to wear out. We are talking about the manufacturing and mining industries. And here business faces another problem: logistics chains have lengthened, the number of processes has increased, hence the delivery time and cost have increased.

We have our own serious expertise in the design and construction of industrial facilities. And our team of experts takes on tasks of any complexity. We also understand equipment and can provide foreign trade services, including logistics. There are ready-made financial tools and solutions to fully equip an industrial plant.

Everything is changing on a daily basis. And logistics in design has now taken on new colors. For the same facility modernization or equipment replacement, which is directly related to the project documentation, more actions and more tasks are required. In addition, everyone knows about the volatility of currency exchange rates and problems with bank transfers even between Russia and China.

- How does interaction with supervisory authorities look today?

- I would say not much, but it is changing for the better. Bodies such as Glavgosekspertiza or Rostechnadzor are paying considerable attention to the digitalization of some bureaucratic processes, as well as the digitization of data. This simplifies tasks and shortens service delivery times.

At the same time, the supervisory authorities make a lot of demands. Although they are justified, this often results in long waiting times for businesses. As a result, costs increase, and at the same time supervisory authorities may suspend the operation of the facility. In other words, the business faces difficulties on all fronts - both financially (it has to pay contractors and not get profit from the facility's operations) and reputationally. TKB.RF, being a subordinate structure of Rostechnadzor, helps with support from the design of the facility to the moment of receiving a positive conclusion from Glavgosexpertiza, which allows the business to move forward.

- How would you assess the degree of implementation of the state policy on digitalization in industry?

- I would like to note right away that industrial enterprises have all the necessary degree of digitalization for the implementation of current economic tasks related to their activities. At the same time, the state does not need all this huge array of data coming from the enterprise. What it needs is control, information about risk factors that could lead to any problems at production facilities caused by violations of industrial safety, environmental legislation, and so on. To keep a finger on the pulse, but not to interfere in the economic activity of the company. Accordingly, the key problem is to connect the digital systems of production companies and supervisory authorities.

This is exactly the kind of activity that TCB.RF is engaged in, building such a digital gateway. It is called a remote control system, which is currently being implemented as part of a government experiment and allows the state supervisory authority, in particular Rostechnadzor, to have a necessary and sufficient amount of information from a particular industrial enterprise. Analysis of such information allows to draw conclusions about the need to check this or that enterprise. Moreover, such a system is beneficial to both the state and business. If an enterprise is connected to remote control, the number of inspections is drastically reduced. If a company is open to the state, what is the point of checking it.

The activities I have mentioned include many complex processes that take place at different times and are specific, but are interconnected. Big business often fragments these activities. That is, instead of identifying the task at hand as a portfolio of projects, they see several separate projects that are most often handled by different organizations. And even if a separate professional team is engaged in each area, the large project itself may not take place on time due to the lack of constant control and systematic consolidation of relevant information about the project's progress.

This is where turnkey solutions, which allow for comprehensive management of the entire project - from the collection of initial data to commissioning of the facility - become particularly important. In the realities of modern Russia it is difficult to overestimate the importance of quality and timely implementation of any large project. National security depends on it in the first place.

- It turns out that this is the most optimal approach to achieving your goals?

- Exactly so. When the entire process is controlled by one organization, the achievement of the client company's strategic goals is guaranteed. Because there is prompt access to information, so you can react to any changes in the course of the project in a timely manner and be proactive - manage risks.

- You spoke about the protection of objects from drone attacks...

- This is a very important topic, but it is poorly developed. Even at the legislative level, not enough decisions and laws have been adopted. And this is the protection of facilities and the population - their safety. Unfortunately, and this is typical of businesses in absolutely different spheres, a lot of things are tied up in financing. It is possible to protect an object from a drone with the help of physical structures, by physical destruction of the drone in the air, as well as with the help of means of electronic warfare (REB). Based on the current practice, it can be concluded that all available defense measures should be applied to fully secure the facility. Thus, in addition to the purchase of suitable REB means, competent designers are also needed. And TKB.RF is also engaged in this kind of activity, providing services for comprehensive protection of enterprises from drone attacks.

- How do you see the future of the industrial and construction industry?

- I would say moderately optimistic. There are a number of factors in favor of a positive scenario for the development of the situation in the Russian industry. For example, the industry has not yet realized the full potential of the post-crisis recovery associated with the development by Russian manufacturers of niches in the domestic market that were vacated after the departure of foreign companies. This is the first point of growth. The second point of growth is the military-industrial complex, which is pulling a huge sector of the economy behind it. And the third is infrastructure construction.

The industrial decline due to the imposition of anti-Russian sanctions was overcome by June 2023, after which there is a general stabilization. Industrial production data is also positive, with growth of 4.8% in October.

Many new large construction projects are also being launched, not only in Russia but also in the CIS countries. This is a huge market with great prospects.