The era of electric mobility: how the launch of gigafactories will change the market

- Статьи

- Local news

- The era of electric mobility: how the launch of gigafactories will change the market

The Kaliningrad region is preparing to launch Russia's first gigafactory for the production of lithium-ion batteries. The event, which will take place in December, is a huge contribution to the development of the electric mobility industry, the importance of which for industry and technology cannot be overestimated, experts say. Read about why the launch of a new enterprise is especially important for the Russian market in the Izvestia article.

Price matters

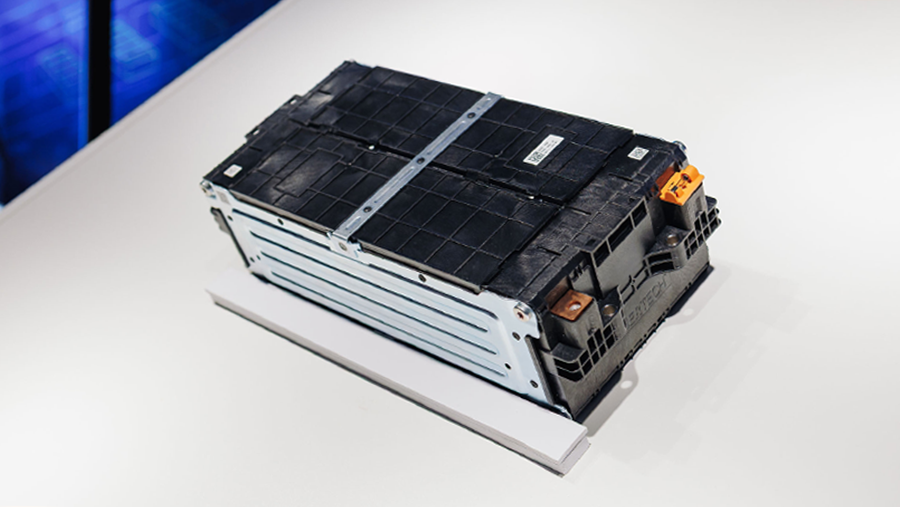

Today, the cost of a battery is up to half the price of an electric car. Until now, this critical component had to be imported, which made the final product more expensive and created dependence on external suppliers. The launch of the gigafactory in Neman is fundamentally changing the situation. The capacity of the enterprise at the first stage will be 4 GWh per year, which is up to 50,000 traction batteries for electric vehicles. In the future, the technology can scale with market development and be replicated in other countries.

— Unlike foreign lithium-ion battery manufacturers focused on passenger electric vehicles, Russian production is focused on a wide B2B segment: urban electric transport (electric buses, trams, river electric vessels), electric special equipment, compact urban solutions for private households, stationary systems for electricity distribution (container type) designed to unload power grids during peak periods periods. This approach is ensured by a full production cycle, from the extraction of raw materials to the production of strategically important battery components and their subsequent processing, which guarantees independence from imports and reduces production costs in the long term," emphasizes Anastasia Mikhailova, CEO of RENERA (part of Rosatom's Fuel Division).

The production of Russian batteries is a way to reduce the cost and increase the availability of electric vehicles for ordinary consumers. The project is implemented on the principle of "smart manufacturing": the lines are 90% automated, and digital quality control systems can reduce costs and increase the stability of the technological cycle. This is a significant step towards the country's technological independence and the creation of a strong export potential in the field of energy storage systems.

— The launch of gigafactories creates the basis for the development of a local and industrial ecosystem. In fact, this is an important infrastructure project, around which a whole chain of related areas will develop — from component suppliers to service companies, that is, it will ensure control of the entire life cycle of manufactured batteries," says Alexander Bukhvalov, director of the Electromobility business area of the Rosatom Fuel Division.

Under the Russian realities

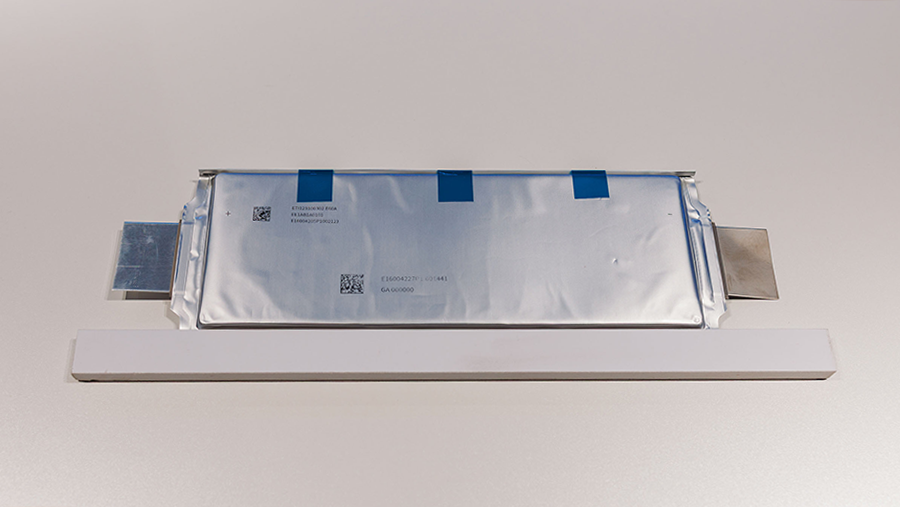

The basic products of the gigafactory will be lithium-ion batteries with a cathode based on NMC (nickel-manganese-cobalt). This option was not chosen by chance. Such a battery has a high energy consumption, which increases the power reserve — a key parameter for Russia with its distances. Compared to other technologies such as LFP, NMC allows you to either get a more powerful battery with the same dimensions, or make it more compact and lighter, which is especially important for commercial vehicles.

—Lithium-ion solutions fit well into a flexible product line: from traction batteries for transport to stationary storage devices for networks and charging station infrastructure," notes Alexander Bukhvalov.

The main feature is a complete adaptation to the Russian climate. The batteries are designed for stable operation at low temperatures and will be equipped with advanced thermostating systems, surpassing the product solutions of world leaders in this indicator. The cold winter is no longer an obstacle for electric transport. Each battery is equipped with the most advanced monitoring and control systems (MCUs), which allows you to unlock the advantages of NMC in terms of energy intensity while strictly complying with resource and safety requirements.

— In short, the key feature of our batteries is not only localization, but the creation of a product with excellent performance characteristics, originally designed for Russian conditions. We focus on increased specific battery parameters, operational life and safety," confirms Anastasia Mikhailova.

A look into the future

Active research and development is already underway in the field of post-lithium technologies, sodium—ion, which will find application in stationary energy storage devices. Such batteries will be much cheaper because they do not depend on scarce and expensive lithium, cobalt and nickel. And what is especially important, they also demonstrate effective operation in negative temperatures.

In parallel, scientific and applied developments are underway in the field of creating promising batteries based on LFP/LMFP and post-lithium — solid-state batteries, which promise to improve operational safety. The gigafactory's production facilities are initially designed to be flexible so that it can quickly and seamlessly switch between different technologies as the market evolves.

The next step after reaching its design capacity will be the launch of a second gigafactory in Krasnaya Pakhra, which will produce batteries to meet the needs of the capital and the growing demands on the comfort of the urban environment from Muscovites.

Full cycle

From the very beginning, the project strategy is aimed at maximizing the localization of components. Cooperative chains have already been established with domestic suppliers of aluminum and copper components, anode binders, separators and electrolytes. Cathode materials that were previously imported will soon be produced domestically thanks to active work with Russian scientific institutes and industrial enterprises.

The estimated battery life reaches up to 10 years or up to 5 thousand / 8 thousand full charge-discharge cycles, depending on the application. At the same time, the traction battery, after being used in electric vehicles, will be able to find application in stationary energy storage systems for solar power plants or backup power systems.

And when the resource is completely exhausted, the batteries will be recycled. Rosatom is already building the country's first lithium-ion battery recycling facility in Dzerzhinsk, which will include seven automated lines.

— The production capacity of the complex is up to 25 thousand tons of batteries per year, and during processing it is planned to extract about 15 types of secondary useful materials, including aluminum, copper, nickel, cobalt and lithium—containing concentrates. This will allow the extracted components to be recycled in the production of new batteries, forming a closed cycle of battery circulation," notes Alexander Bukhvalov.

Thus, a full—fledged closed cycle is formed - from the production of raw materials to the disposal and return of valuable materials to production, which is fundamentally important from an environmental and economic point of view.

Safety is a priority

Battery safety is a subject of special attention. Based on global experience, a new direction has been initiated — a service center that will be able to remotely analyze the battery status. Thanks to telematics, it is possible to track the condition of any battery and prevent its overheating or integrity violations. This creates a unique model that will form the basis of future, even more efficient and secure technologies. The R&D center provides a full service cycle: from warranty repairs and round-the-clock support to monitoring for urban infrastructure and partner training.

— Special attention is paid to the environmental component. A closed water circulation system is being implemented, waste-free production solutions are being implemented, and energy-efficient technologies are being applied. The issue of diversifying sources of lithium raw materials is under constant control to ensure the stable operation of the enterprise, and the reliability of energy supply is guaranteed by a well—thought-out infrastructure," notes Anastasia Mikhailova.

Thus, the gigafactory is not just a production complex, but an ecosystem combining advanced technologies, efficient logistics and environmentally friendly solutions.

The start of a large construction site

The Kaliningrad gigafactory is just the beginning. Already in 2026, a second similar enterprise will be launched in Krasnaya Pakhra (Troitskiy district), focused on the needs of the capital region. And the overall development schedule includes the creation of a network of four gigafactories by 2030. The combined capacity of the first two plants will exceed 8 GWh per year, which is about 100,000 batteries for electric vehicles.

— Car factories will be able to receive batteries within the country, which means stable supplies, reduction of logistical costs and various risks. This will give an impetus to the development of domestic engineering, the launch of new projects in urban and special transport, including in the segment of electric trucks," emphasizes Alexander Bukhvalov.

Thus, the opening of the first gigafactory will become the starting point for a new, technologically independent era of Russian electric mobility.

Переведено сервисом «Яндекс Переводчик»