- Статьи

- Science and technology

- In hardware form: scientists have created an innovative flexible X-ray material

In hardware form: scientists have created an innovative flexible X-ray material

MSU scientists have created a material that can be used to make flexible screens for X-ray machines. They are used to enhance the X-ray radiation and shorten the procedure time. The technology allows you to get an image with better detail and a lower radiation dose. As experts told Izvestia, the development is promising for the creation of diagnostic equipment in dentistry or orthopedics, mechanical engineering, where examination of uneven surfaces is required, and the creation of portable devices for radiography.

Why does X-ray need a flexible screen

Scientists from the Faculty of Materials Sciences of Lomonosov Moscow State University have proposed a new material based on a coordination polymer capable of efficiently converting X-rays into visible light. The development opens up prospects for the creation of flexible, stable and high-resolution scintillation screens (capable of emitting light when exposed to ionizing radiation), which are in demand in medicine and industry.

According to the developers, the new material combines high photoluminescence efficiency (up to 98.5%), resistance to moisture and temperatures up to 300 ° C, as well as stability under the influence of high doses of X-ray radiation.

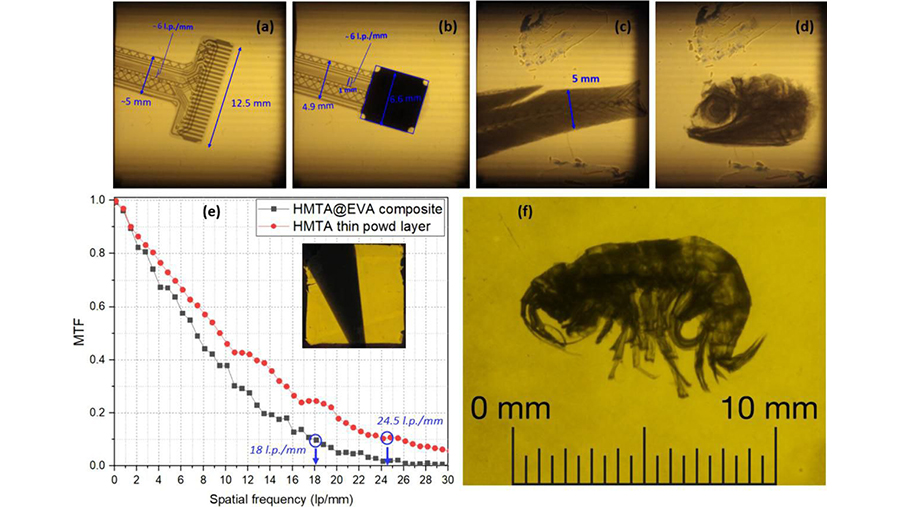

The scientists used available substances copper(I) iodide and urotropin to produce scintillator nanoparticles, which were then embedded in a flexible polymer matrix made of ethylene vinyl acetate (a lightweight, elastic and flexible material that is widely used in the manufacture of various products). The resulting composite screens demonstrated high brightness of X-ray luminescence and high resolution, surpassing the characteristics of most commercial analogues, MSU said.

"Our material demonstrates a combination of unique properties — high luminosity, mechanical flexibility, and resistance to moisture and harsh radiation — which makes it a universal solution for X—ray imaging tasks," said Sergey Fateev, one of the authors of the work.

The screens created on the basis of the new material allow you to get clear images of small objects and details, while remaining durable and lightweight. According to scientists, they can be used as flexible scintillators for X-ray imaging tasks.

"It was important for us to create not just an efficient scintillator, but a material that can be produced on a large scale and integrated into flexible devices without loss of performance," said Alexey Tarasov, head of the Laboratory of New Materials for Solar Energy at the Moscow State University, where the research was conducted.

Prospects for new material

Flexible X—ray screens are especially relevant in medicine, where they allow precise wrapping of sensors around the patient's body - this is especially important when visualizing joints, chest, head and other anatomically complex areas, said Albert Rizvanov, head of the Center for Excellence "Personalized Medicine" at Kazan (Volga Region) Federal University, corresponding member of the Academy of Sciences of the Republic of Tatarstan.

— Such contact improves image quality, reduces artifacts and can reduce the required radiation dose. Similar developments are underway in the world, but many materials, such as quantum dots or organic scintillators, are unstable to moisture, temperature, or X-rays. The novelty of MSU's approach is to create a material with high brightness, flexibility and heat resistance, which opens up the prospect for safer and more accurate diagnostics in clinical practice," the specialist told Izvestia.

Unlike traditional rigid screens, the new material based on a coordination polymer has mechanical flexibility. This allows it to be used in devices with non—standard geometries, for example, for examining curved surfaces, said Anton Averyanov, CEO of the ST IT Group of companies, TechNet NTI market expert.

— Even the increased radiation conversion efficiency of up to 98.5% already surpasses many commercial analogues, which gives the material an additional advantage — it provides a clear image of small details. Flexibility also makes it possible to adapt the material to complex body shapes, improving the quality of diagnostics in dentistry or orthopedics, and even in mechanical engineering, where examination of uneven surfaces is required. Also, thanks to them, we can try to create compact and, possibly, even portable devices for radiography," the expert added.

X-ray detection is used in medical diagnostics (fluorography and other procedures), product flaw detection in production control (turbine blades), space exploration devices, for monitoring at nuclear power plants and in other industries, explained Evgeny Bauman, Director of the NTI Center for Digital Materials Science: New Materials and Substances at the Bauman Moscow State Technical University. Alexandrov.

— Detection using scintillation materials helps to visualize X-rays with lower cost, faster response, and high resolution. For the introduction of new materials, it is necessary to overcome difficulties with the consistency of quality and stability of materials," he said.

The work was carried out with the support of the Russian Science Foundation.

Переведено сервисом «Яндекс Переводчик»